Roundtop Machinery Industries Co., Ltd

VMC / SV Series

We offer the following:

VMC-850/1050

JET-32/40

SV-33/41/33H/41H

SV-48/48H

VMC-1300/1300HD/1300-2H

VMC-1600/1600HD/1600S/1600SHD

VMC-3000S/3000SHD

VMC-2000S/2000SHD

VMC-850/1050+APC JET-32+APC

VMC-1300/1600 +APC

SV -33/41+APC

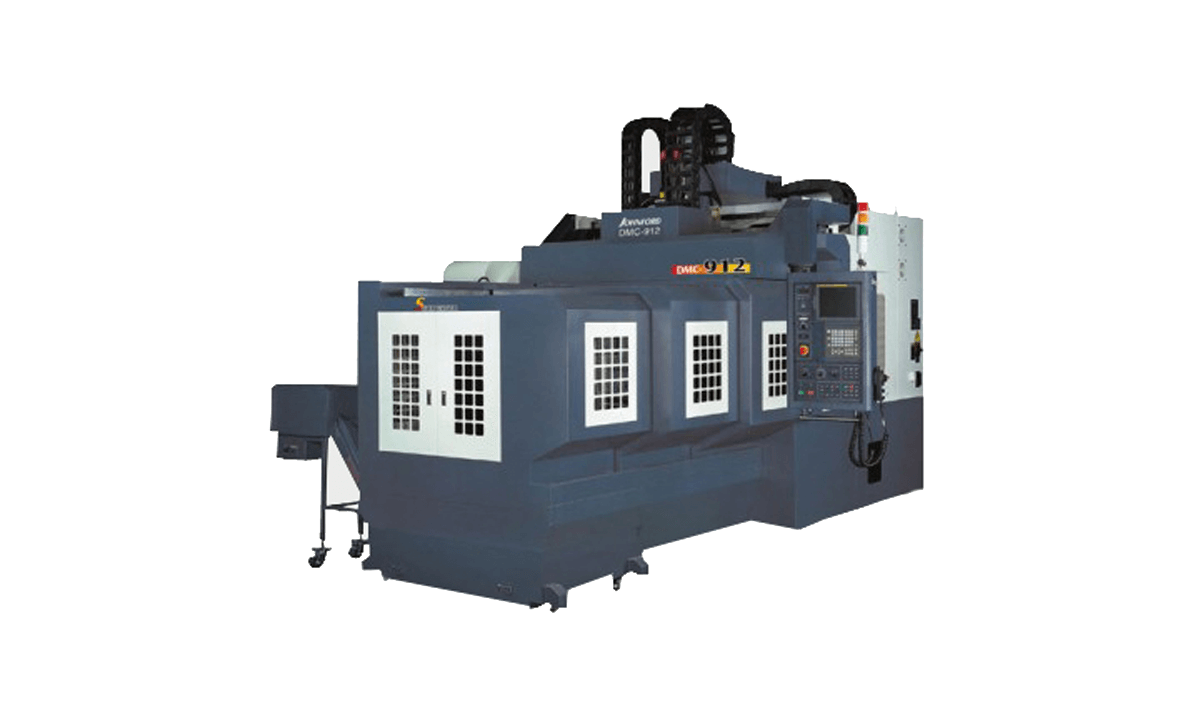

JET/ DMC Series

We offer the following:

JET-1000

DMC-909/912/915

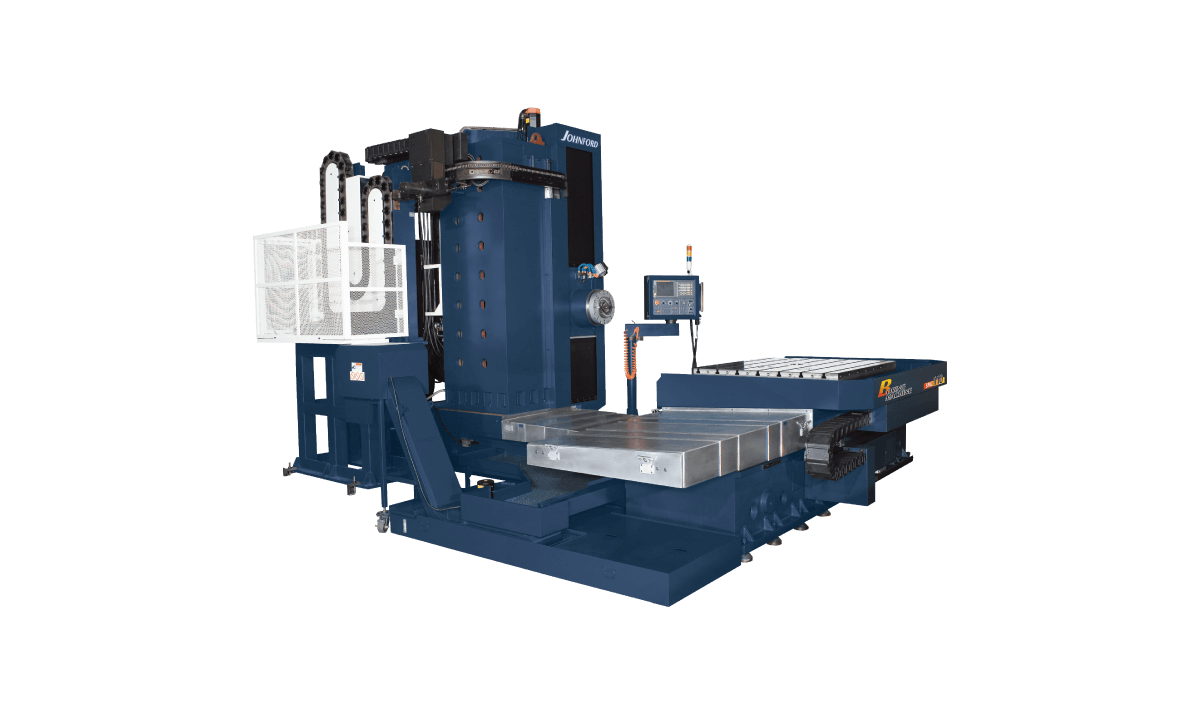

BMC Series

Johnford delivers the NEW BMC-110, the heaviest horizontal boring mill in its class. This 35 HP workhorse weights in at a hefty 55,000 lb. of Meehanite cast iron. The BMC-110 delivers outstanding rigidity and accuracy at a great price.

We offer the following:

BMC-110/130/160

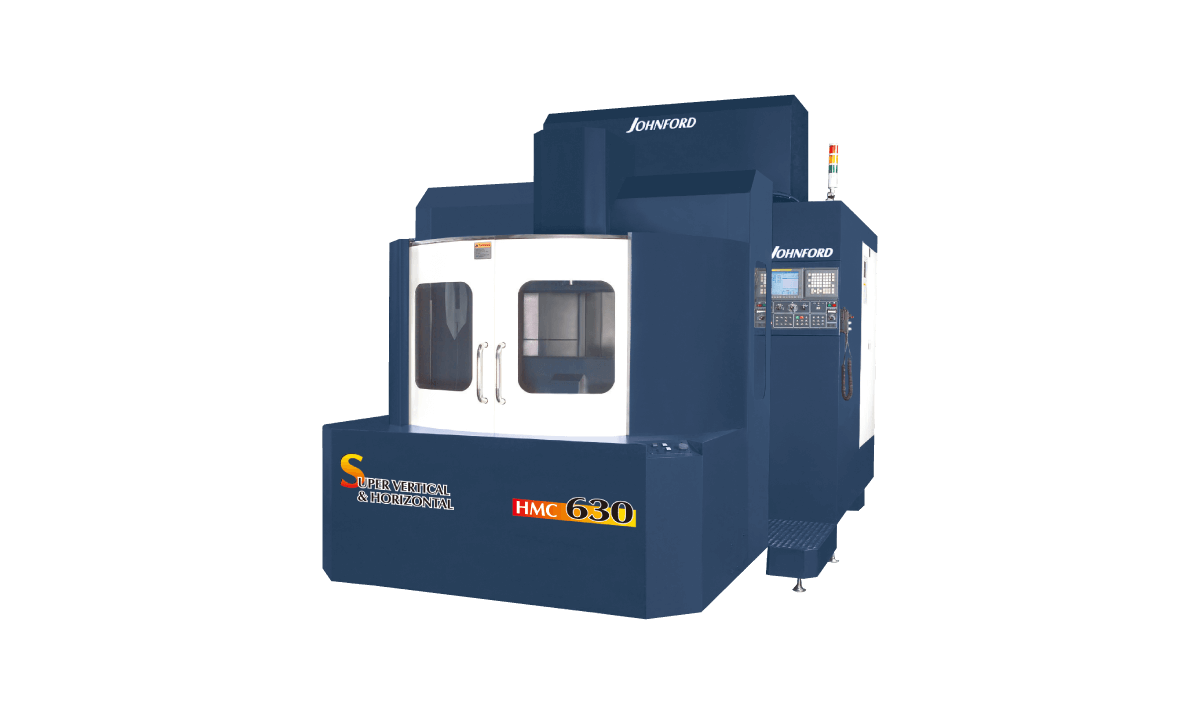

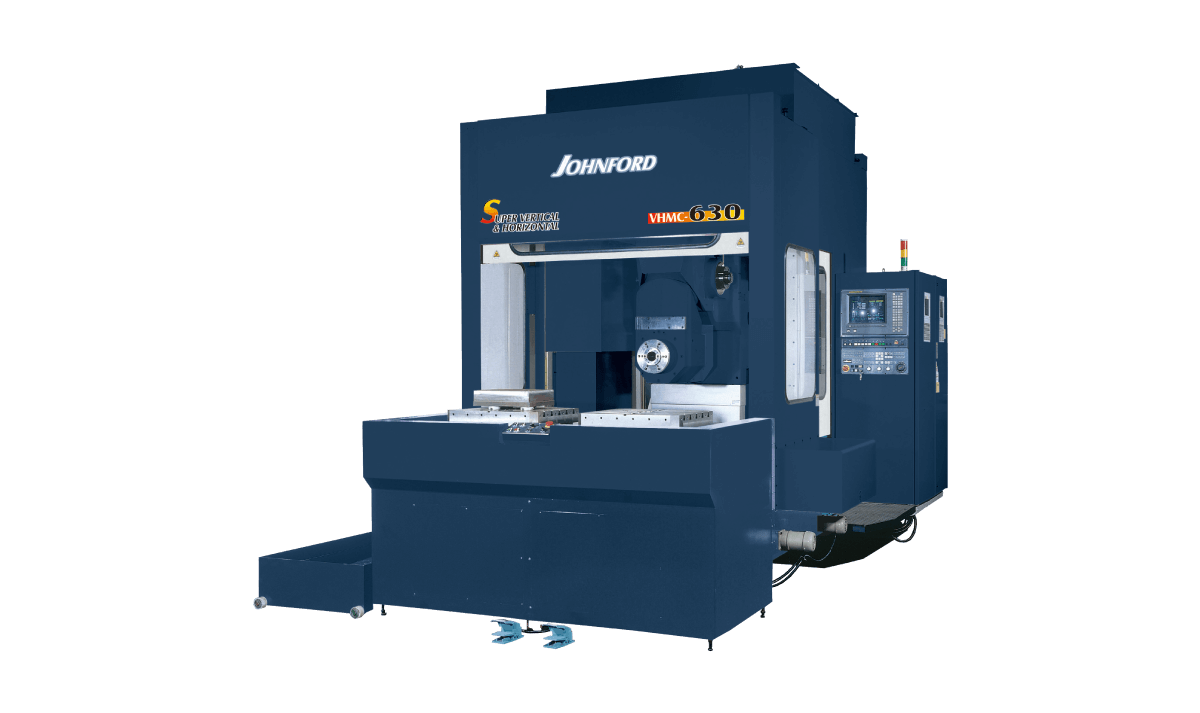

HMC Series

The HMC series machining centers are designed with the symmetrical “Box in Box” structure. It can reduce thermal growth and make the machine more stable. The spindle of machine is the direct-driving or built-in type. With the high-speed construction, the HMC series machining centers can provide you faster processing efficiency and more careful machining quality.

We offer the following:

HMC-500/500H/630/630H

HMC-800/1000H

VHMC-630

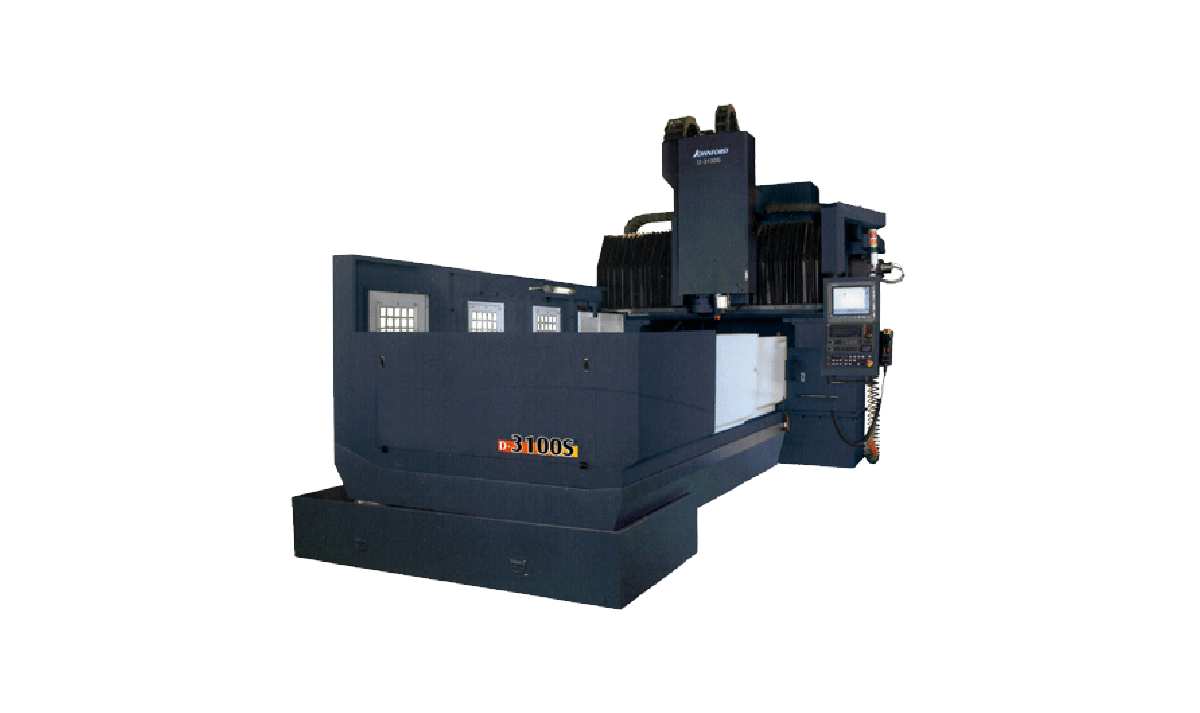

DMC Series (Small&medium size)

Adhering to our outstanding quality and development experience on the vertical machining centers for many years,the series of vertical high-speed machining centers can provide you faster processing efficiency and more careful machining quality. Expanding on our popular DMC series of large frame bridge mills, this series of high-speed bridge mills can take the place of large C-frame type mills while still offering value-based pricing.

We offer the following:

DMC-900 / 1200 / 1500 / 900H / 1200H / 1500H

DMC-1600/2100/3100/4100/1600H/2100H/3100H/4100H

DMC-2100S / 2600S / 3100S / 4100S / 5100S / 6100S / 2100SH / 2600SH / 3100SH / 4100SH / 5100SH / 6100SH

DMC-3100P / 4100P / 3100PH / 4100PH

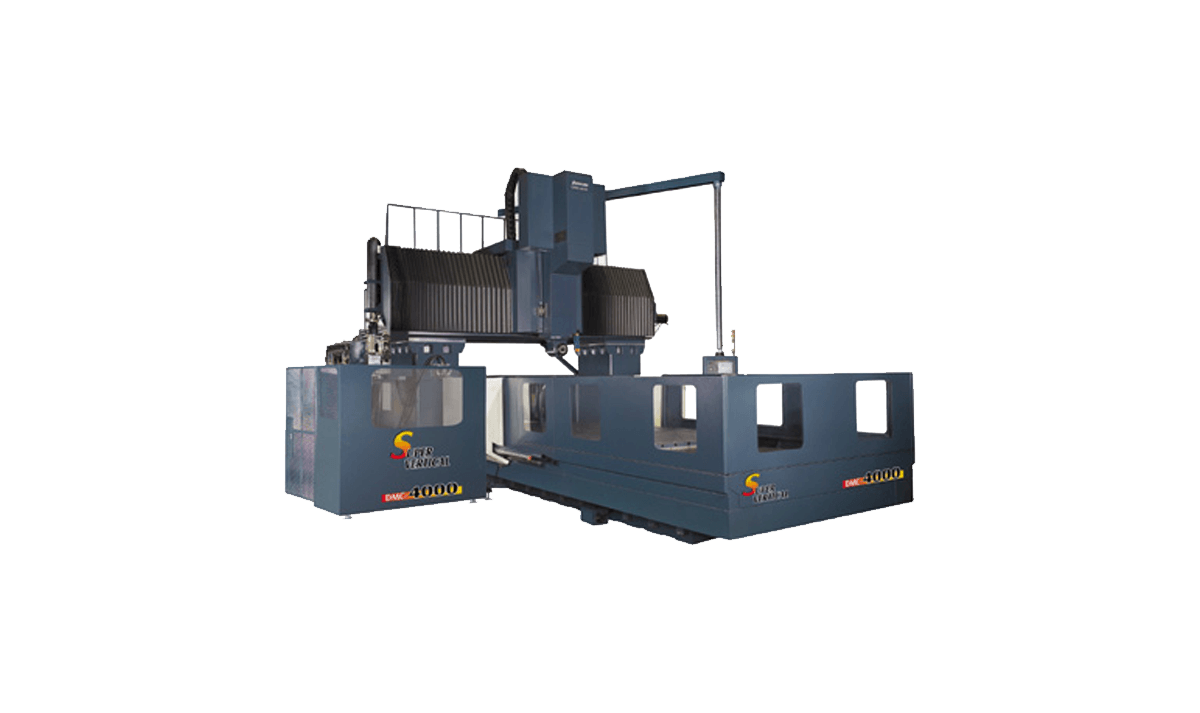

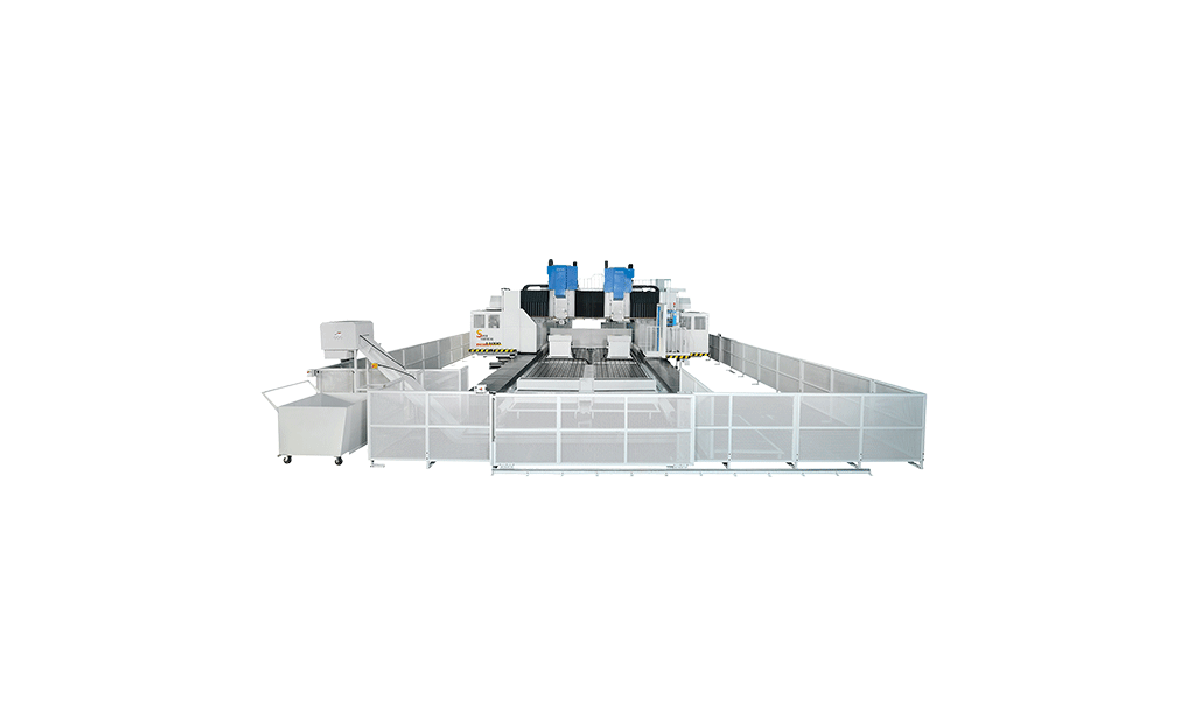

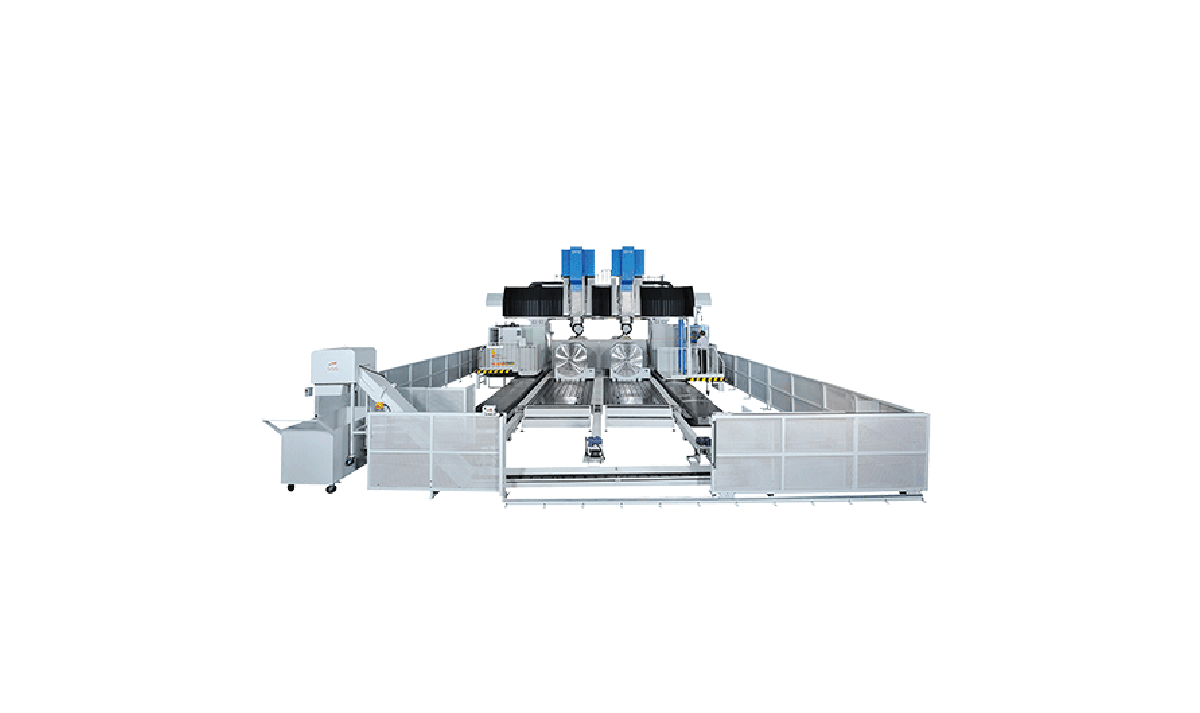

DMC Series (Large size)

The structures of major components of DMC’s machining centers have been designed with the finite element analysis (FEA). By this way, we refine our design and improve product quality. They can offer high rigidity and good precision that are for beyond ordinary.

We offer the following:

DMC-4000X2800X800 / DMC-4000X2800X1066 / DMC-4000X2800-R2 / DMC-4000X2800+5F

SDMC-6000X2800X800 / SDMC-6000X2800X1066

SL Series

JOHNFORD CNC Super Lathes are under strict engineering, building and test to provide you the best machining quality. The CNC Super Lathes also bring you profitable operations. JOHNFORD’s outstanding technology experience will help you to achieve a mass production and reduce the cost.

We offer the following:

SL-20/30/40/40L

SL-35

SL-35-2S (SUB SPINDLE SERIES)

SL-50/50A/50B

SL-50-2S/SL-50A-2S (SUB SPINDLE SERIES)

SL-60/60A/60B

SL-60-2S/SL-60A-2S (SUB SPINDLE SERIES)

SL-65/65A/65B

SL-70A/80A/100A/120A/70B/80B/100B/120B

SL-70A-2S/80A-2S/100A-2S(SUB SPINDLE SERIES)

ST Series

The JOHNFORD ST series SUPER TURNING centers are exclusively designed to not only meet today’s needs, but also future requirements. These turning centers give you the very finest in turning technology. Rugged construction assures optimum rigidity and stability for years of reliable, and trouble free operation. furthermore, these machines offer the turning accuracy and efficiency that are for beyond ordinary.

We offer the following:

ST-40A/60A/70A/40B/60B/70B/40C/60C/70C

ST-80B/100B/130B/160B/200B/240B/80C/100C/130C/160C/200C/240C/80D/100D/130D/160D/200D/240D

ST-40AH/60AH/70AH/40BH/60BH/70BH/40CH/60CH/70CH

ST-80BH/100BH/130BH/160BH/200BH/240BH/80CH/100CH/130CH/160CH/200CH/240CH/80DH/100DH/130DH/160DH/200DH/240DH

ST-40AX/60AX/70AX/40BX/60BX/70BX/40CX/60CX/70CX

ST-80BX/ 100BX/ 130BX/ 160BX/ 200BX/ 240BX/ 80CX/ 100CX/ 130CX/ 160CX/ 200CX/ 240CX/ 80DX/ 100DX/ 130DX/ 160DX/ 200DX/ 240DX

HT Series

The JOHNFORD HT Series High Quality Turning Centers are designed out of the ordinary to meet what you need not only today, but also in the future. The HT Series starts with a time proven slant bed design for rigidity, chip flow, accessibility, and space saving characteristics. These machines are built for outstanding performance in medium and large lot production runs. They always deliver the precision and efficiency that are far beyond the ordinary.

We offer the following:

HT-30-2S/ 35-2S/ 40-2S/ 60-2S/ 80-2S/ 100-2S

HT-30-2D/ 35-2D/ 40-2D/ 60-2D/ 80-2D/ 100-2D

HT-30-2SD/ 35-2SD/ 40-2SD/ 60-2SD/ 80-2SD/ 100-2SD

GT Series

JOHNFORD offers you the best performance in large turning centers with our advanced manufacturing ability.

We offer the following:

GT- 40/80/120/160/200/240/275/320/355/395

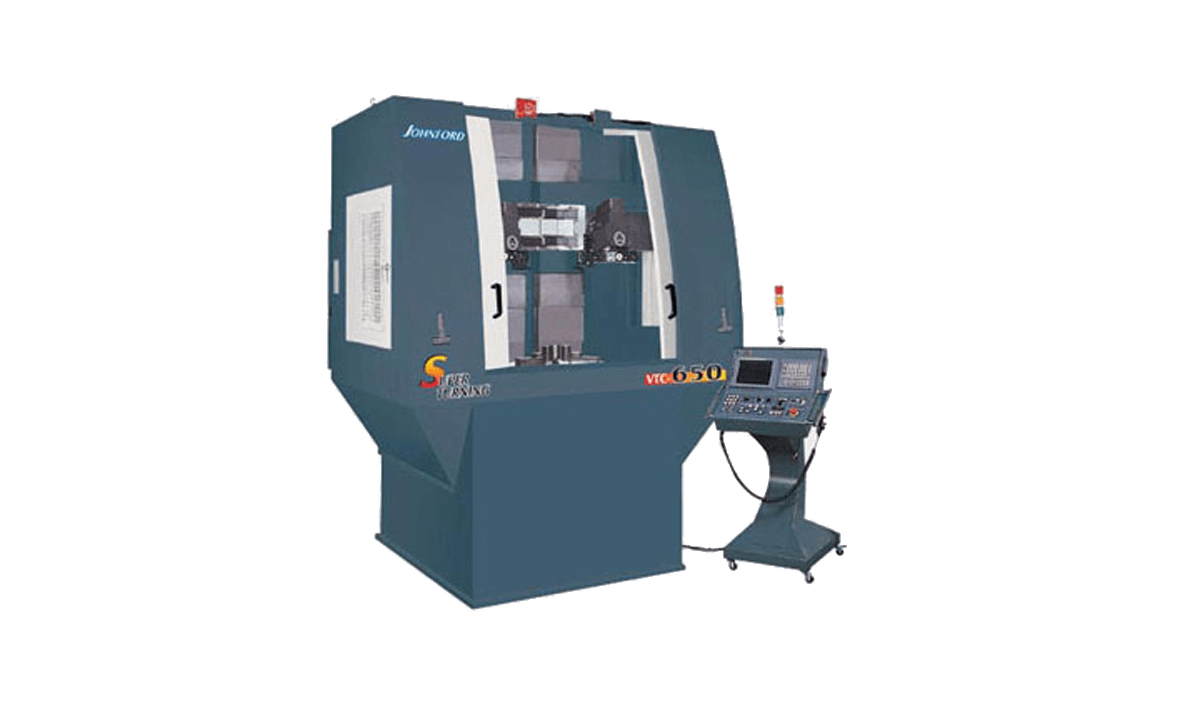

VTC Series

These series machines are designed for heavy machining of large workpiece. With APC (Automatic Pallet Changer) design, it makes loading or unloading workpiece easy and reduces the idle time of machine. The design of double turrets can reduce cutting time and machining operations of machine.

We offer the following:

VTC-650

VTC-800ATC/1000ATC

VTC-1200ATC/1600ATC

VTC-2000ATC/2500ATC/3000ATC/4000ATC/5000ATC/6000ATC

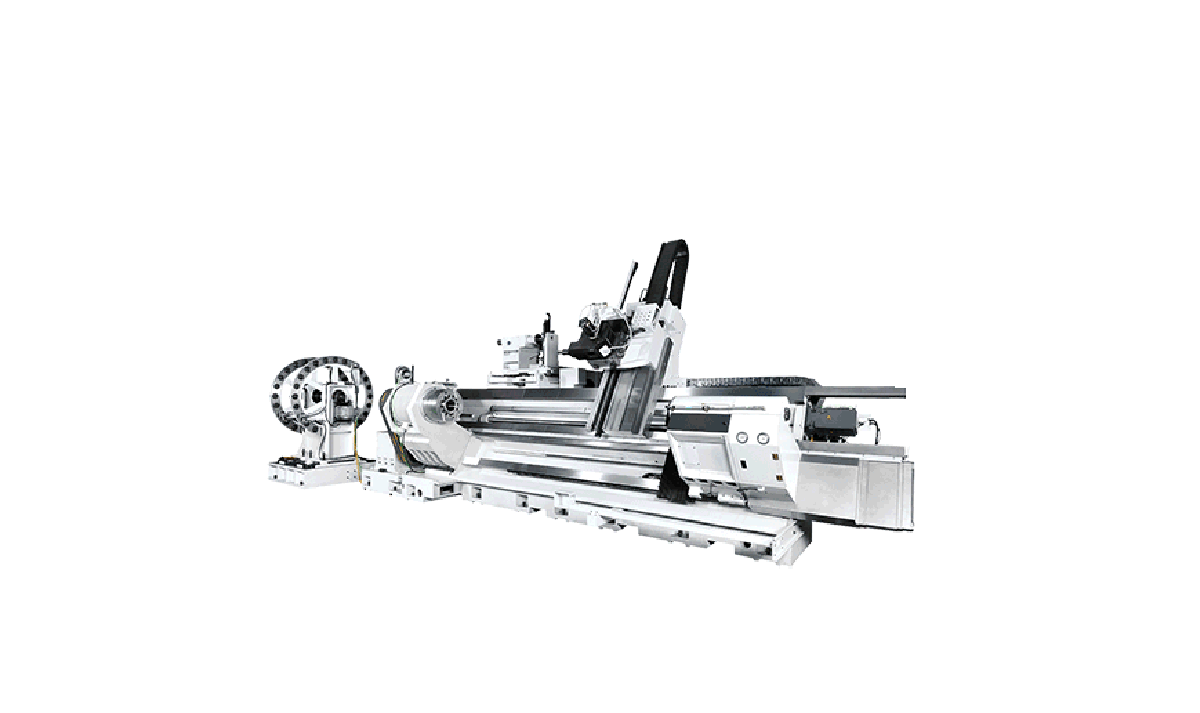

LC / SCM Series

The Johnford LC/SCM series is a large, heavy duty, high precision flat bed CNC turning center. The precision spindle structure is supported by precision double row cylindrical roller bearings or high precision taper roller bearings. The bed is a one piece floor to floor Meehanite casting and provides efficient free flow of chips and ease of operator accessibility. The bed has with 3 ways for the ability to turn through the steady rest. The center way on the bed is actually two ways in one and is shared by both the cross slide and the steady rests or other equipment mounted on the back ways. Due to the length of the machine, the Z axis ballscrew is stationary and the ball nut rotates. This eliminates screw whip and vibration. A massive automatic vertical 12 tool turret with a 12” thick tool disk provides fast indexing, as well as coolant through the tool holders. The turret has boring bar capacity of up to 6”. Other turrets and configuration are available including front and rear turrets. The machine is well equipped with the coolant system, work light, 3 jaw hydraulic chuck or 4 jaw manual independent chuck, dual chain type chip conveyors, programmable tailstock with live quill, and the safety guarding as standard accessory.

We offer the following:

SCM-3000/4000/5000/6000/7000

LC-40/50/60

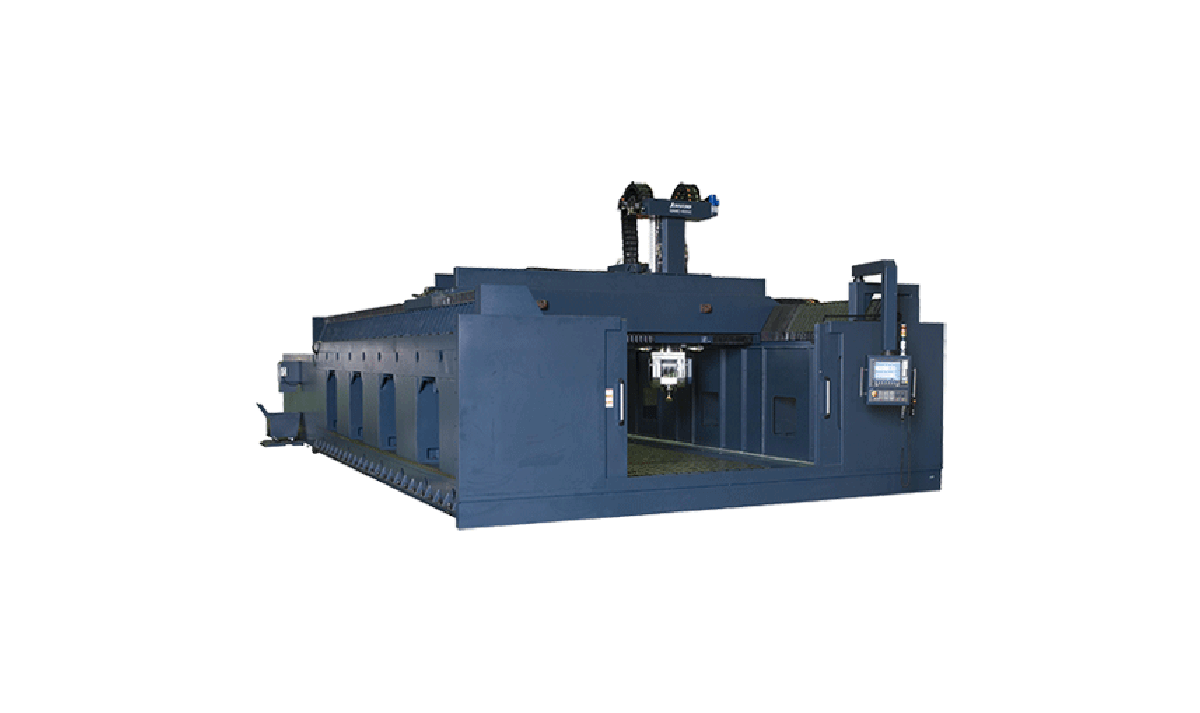

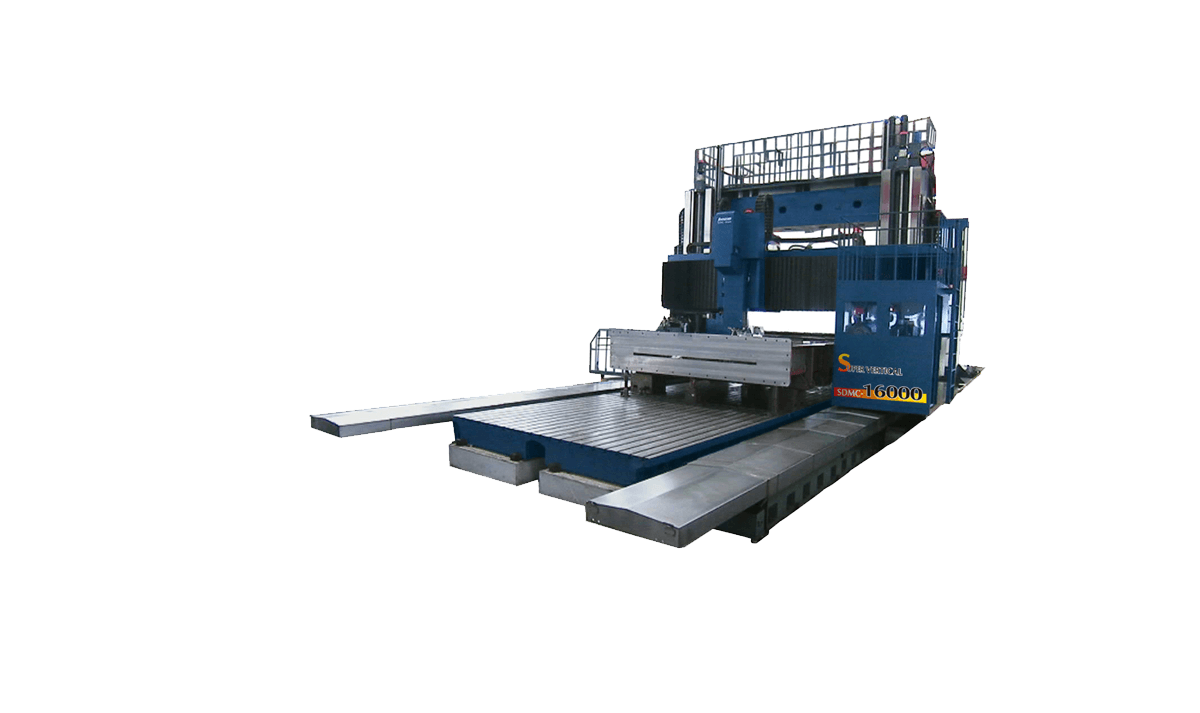

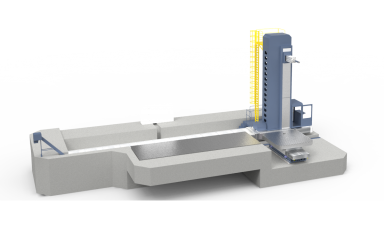

GMC Series

The Johnford GMC series is a combination of speed, rigidity and precision heavy duty gantry type machining center. The machine design features a moving bridge on two platforms and fixed table for unlimited table loads. The main structures of machine are constructed with Meehanite cast iron. Starting at 3 meters of X travel, the GMC series can be expanded up to 20 meters of X travel. This machine can also be equipped with linear motors or preloaded rack & pinion drives to expand the distance of what you want in X travel. The CNC synchronizes the servo motors to eliminate the crabbing effect. Twin Heidenhain glass scales are standard on the X axis to enhance positioning accuracy. There are two types of bridges. One is a Box-in-Box bridge, and the other is rugged bridge with offset Y-axis ways. The lightweight box-in-box bridge supports the headstock with two additional rugged I-beams. But the rugged bridge with offset Y-axis ways and the traveling head have been designed with diagonally arranged ribs that will help reduce the amount of distortion that is caused by years of continued service. Similarly, all types of bridges can be equipped with linear scales for Y-axis moving precision.

We offer the following:

GMC-8000

ORDER MADE

With the abilities of “flexibility” and “customization” in design and manufacture, they are Johnford’s strengths active in the industry for years. Whatever customers need any order-made machines, Johnford is able to provide excellent, reliable and stable products.

We offer the following:

ST-130BX/130CX/130DX

SDMC-11000X3200X1066-2H-5F

SDMC-16000X4600X1400-W

SDMC-11000X3200X1400-2H-TU35

D-1600H/ 2100S/ 3100S/ 4100S/ 5100S/ 6100S/ 2100LH/ 2600LH/ 3100LH/ 4100LH/ 5100LH/ 6100LH/ DMC-3100P/ DMC-3100PH/ DMC-4100P/ DMC-4100PH 數控龍門銑床

FBMC-X85-2H

FBMC SERIES

JOHNFORD’s FBMC series is a floor type boring machining center made for heavy duty and extra-large sized machining. In a standard machine configuration, X, Y, Z & B axes are always equipped with hydrostatic guideways. For the spindle headstock, the standard size is 450 x 520mm. However, a larger size is available as an option. For the 0.001-degree continuous B-axis rotary table, it is always with a hydrostatic system and absolute encoder to guarantee its best accuracy and performance. The parameters and specifications in thie FBMC series are changeable on request.

We offer the following:

FBMC Series