Shop

Averex 540i 2 pallet HMC $300k

Category: CNC Mills

Description

HS-540i GTS Standard Features

-

Fanuc-Averex MPro-I Control with 15” LCD Display

-

2 Meg Memory, AICC II Nano Control with 200 Block Look Ahead, Manual guide I

-

2-Pallets 500mm or 400mm, Field Expandable to 6 or 8 Pallet Pool Systems

-

15,000 RPM 50HP 300NM/250NM IDD Dual Contact CT-40 Taper Spindle with Chiller

-

Tool Load Monitoring (Programable Type)

-

Large 31.5 x 31.5” x 31.5” Travels, With 31.5 x 40” Part Capacities

-

80 Tool Servo Driven Magazine, 120 Tools Field Expandable

-

Thermal Control System: Core Cooled Tsubaki Ball Screws, Thrust Bearings and Mounts, Spindle Cartridge, Spindle Motor and Spindle Separator Housing

-

2,915 IPM Rapids, 1,574 IPM Feedrates with 1.25G+ ACC and DEC rates

-

66 RPM Full Fourth Axis Contouring Table with 4 Axis Simultaneous

-

Pressurized Oil and Air Lubrication for the Spindle, Roller Ways and Ball Screws

-

435 PSI (30 Bar) Through Spindle Coolant

-

Thru-Spindle Air Cutting (M-code)

-

4-Kosmek Ball Lock Mechanical Pallet Clamping System

-

7 Day Programable Timer for Machine Auto Power Start Up and Shut Down

-

Dual Chip Augers, Multiple Style Conveyors Available

-

4 Nozzle Over Head Pallet Wash

HS-540i GTS Main Machine FeaturesPallet Size……………… 500mm x 500 mm (Std.)400 mm x 400 mm (Opt.)Number of Pallets………………………………………………………………. 2 (Expandable to 6 or 8 pallets)Standard Spindle……15,000 min-1 (50HP)300NM-2 Min 250 NM-15 MinTool Shank Size……………………… Dual Contact 40 Taper Big Plus®X-Axis Travel…………………………………………………………………….. 31.5”Y-Axis Travel…………………………………………………………………….. 31.5”Z-Axis Travel…………………………………………………………………….. 31.5”B-Axis Increment 66 RPM Full 4th Rotary Table1° Indexing (Optional)Rapid Traverse………………….2,913”/min. (THK™ Roller Ways)Cutting Feedrates…………………………………………….1,574”/min.Acc/Dec X / Y / Z Axis………………………….. 1.25G / 1.25G / 1.2GTool Change Time………………………………………. .9-1.0 secondsThrough Spindle Coolant…………. 435 PSI (1000 PSI Optional)Weight………………………………….. 26,900 lbs. (80ATC 2-pallet)

Travels:X-Axis Travel……………………………………………………..31.5”Y-Axis Travel……………………………………………………..31.5”Z-Axis Travel……………………………………………………..31.5”Table Index……………………………Full 4th Rotary, 66 RPMMaximum Weight…………………………..1,210 Lbs. /palletWorkpiece Diameter………………………………………….31.5”Workpiece Height……………………………………………..39.4”Spindle Center to Pallet top……………………1.97”– 33.5”Spindle Nose to Pallet Center……………….3.94”– 35.45”*Accuracy (ISO 10791-4) …………..0.00019” Full Stroke*Repeatability (ISO 10791-4) …….0.00011” Full StrokeBall Screws & Drives:Ball Screws (Core Cooled / Tsubaki™ – Manufacturer)1.6” x .787” (40 x 25MM) Pitch -

X, Y, Z Axial Thrust……………………….…………11,760 NMX/Y/Z Fanuc Motors.…………………………..7.3/7.3/6.0 HPB Axis Braking Torque…………….5000 /3500 NM Full 4th

Rotational Torque………………1953 NM

(B-Axis) Fanuc Motor ………..Alpha 22Drives…Fanuc Alpha with HRV-IIIWith Absolute EncodersB-Axis Rotation Speed66 RPM (1 sec. / 90°)Roller Guideways:Manufacturer………………….THK™ / IKO Roller WaysRail Width……………………………………………….. 1.97”Lubrication……………………………. Forced Oil and Air

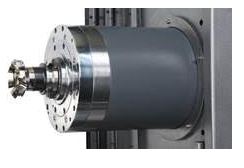

Rigid Headstock & Spindle:

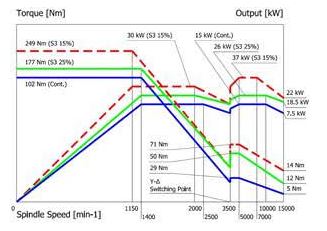

Spindle RPM / HP ……….……15,000 RPM / 50 HP Direct

With Spindle Chiller

Spindle Acceleration….…0-15,000 min-1, ~ 3.0 seconds

Spindle Deceleration……15,000-0 min-1, ~ 3.0 seconds

Spindle Options………..12,000 RPM 65 HP High Torque

Spindle Options…………………….20,000 RPM High Speed

Spindle Taper…………….. CT-40, Big Plus™ Dual Contact

Coolant Through Spindle.…435 PSI (1000 PSI Optional)

Spindle Bearing Diameter….….71 mm / 2.8” – Ceramic

Lubrication…………………Forced Air and Oil Closed Loop

Spindle Torque……..….300NM 2 Min / 250 NM 15 Min

Spindle Motor……………. Alpha 15 / 15,000 min-1 50 HP

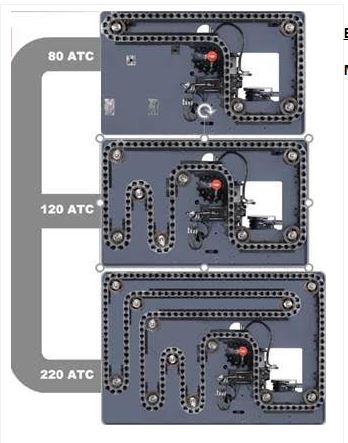

Expandable Tool Changer:

Magazine

Capacity………………………………….….80 Tools

Field Expandable Tool Magazine………………120 Tools

Factory Order ATC…………………………………220 Tools

Tool Shank (Taper)………………CT-40 / BT-40 Optional

Tool Selection…………………………………………………Fixed

Maximum Tool Weight……………………………….…22 Lbs.

Maximum Tool Diameter………………………………..3.75”

Adjacent Stations Empty…………………………………..7.2”

Maximum Tool Length………………………………….15.76”

Tool Change Time (T-T) …………………..……1.5 seconds

Heavy Tool (programmable)………………….2.5 seconds

Chip to Chip Time /Heavy Tool …….4.0 / 4.5 Seconds

Bi-Directional Magazine………………………….. Standard

Magazine Motor………………………..B 12/3000is 2.5 HP

Magazine Rotation Speed……………8 seconds, 80 ATC

Field Expandable Multi Pallet System:

APC Type……………………………………… 2-Pallet Rotary

Field Expandable Pallet Pools…………….. 6 or 8 Pallets

APC Cycle Time……………………………………. 5 seconds

Pallet Location Type……… 4-Kosmek Ball-Lock Cones

Pallet Clamping Force…………………………. 39,200 NM

Height from Floor………………………………………. 42.1”

Pallet Load…………………………… 1,210 Lbs. Per Pallet

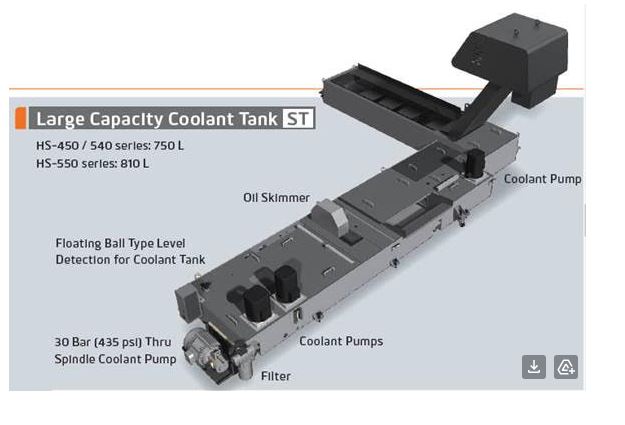

High Efficiency Chip Removal & Coolant System:

All Chip Conveyors Exit to the Front ATC Side of the Machine (rear discharge Optional)

Through Spindle Coolant……………………………………………………….. 435 PSI Std. (1000 PSI Opt.)

|

Coolant Wash Locations:

|

4 Separate Motors

|

Z Axis Covers

|

Pallet Wash

|

Pallet Arm Wash

|

ATC Door Wash

|

Coolant Tank Capacity (2 Tanks) with Level Detection 750 L / 200 US Gallons

Coolant Discharge Flow Rate……. 92 Gallons per minute

Lubrication & Reservoirs:

Ball Screws…………………………… Pressurized Oil & Air

Roller Guide Ways…………………. Pressurized Oil & Air

Spindle………………………………… Pressurized Oil & Air

Hydraulic Capacity………………… 16 Gallons

Hydraulic Discharge Pressure…. 711 PSI

Lubrication Capacity……………… (.5 Gallons)

Electrical & Air Supply:

Machine Electrical Drain – Full Load..50 KVA

Machine Voltage………………….. 220V, 60 HTZ

Central Lubrication Pump……………. 18 Watts

Coolant Pump – Flood (4 separate pumps) 2.1 HP each

Spindle Oil Pump……………….. 1.75 HP

Hydraulic Pump………………… 3.1 HP

Air Pressure Requirement 75 PSI@132 gal/min

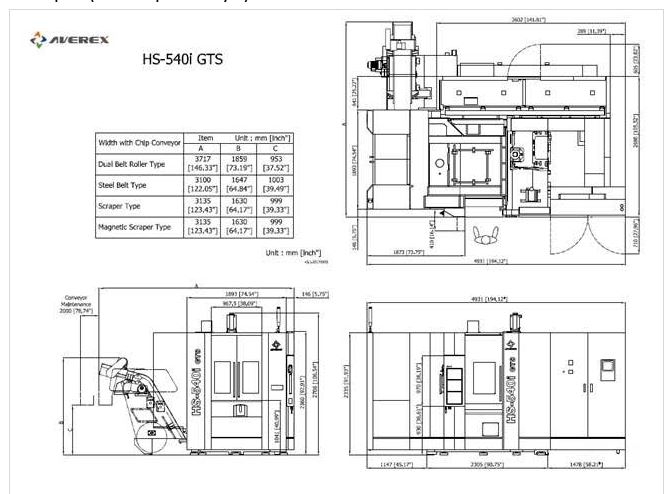

Machine Weight & Dimensions:

Dimensions (2 APC / 80 ATC / Coolant Pan)195” x 127” x 106”

Floor Space (with Scraper Conveyor) …….. 215” x 153” x 106”

Weight (80 ATC / 2 APC)……………………………… 29,800 Lbs.

Averex Fanuc MPro I (Oi-MF Plus) Standard Control Features:

-

15” Color LCD, Full PC keyboard

-

AICC II Nano Control

-

High Speed 200 Block Look Ahead

-

2 Meg Program Storage (5,120 Meters)

-

Simultaneous Controlled Axes, (4) (X, Y, Z, B)

-

Handle Feed Function, X, Y, Z, B Axes

-

1000 Registered Programs

-

48 Pairs Workpiece Coordinates

-

Tool Life Management

-

400 Pair Tool Offsets

-

Coordinate System Rotation

-

HRV-III+ High Performance Axis Drives

-

Feed Clamp/Circular Radius

-

Fine Feed, Acceleration/Deceleration

-

Rapid Traverse Override, 0-100%

-

Ethernet and CF / USB Device

-

Programmable Spindle Load Monitoring

-

Automatic/Memory/MDI

-

Machine Lock, all axes

-

Program Restart

-

Rigid Tapping

-

Stored Stroke Check

-

MDI Operation

-

Stored Pitch Error Compensation

-

Single Block

-

Manual Guide i

-

Auto Corner Override

-

Block Skip Function

-

CRT Display:

-

Big Tool Function

-

Actual Cutting Feedrate Display

-

Help Function

-

Alarm Display

-

Parameter and Settings Display

-

Alarm History

-

Program Display, (program name 31 characters)

-

Servo Tuning Capabilities, Oscilloscope Type

-

Run Hour and Parts Counter

-

Clock Function

-

Self-Diagnostic Function

-

Current Position Display

-

Status Display

-

Program Mirror Image

-

Scaling

-

Chamfer Corner Rounding

-

Playback Function

-

Custom Macros common variable (600-999)

-

Custom Macro B

-

Manual Handle Interruption

-

Ethernet function

-

Dry Run

Interpolation Functions:

-

Circular Interpolation/Multi Quadrant, G02-G03

-

Helical Interpolation

-

Dwell, G04

-

Reference Point Return, G28

-

Exact Stop, G09

-

Reference Point Return Check, G27

-

Linear Interpolation, G01

-

Second Reference Point Return, G30

-

Rapid Positioning, G00

-

Skip Function, G31

Control Features Continued:

Program Input:

-

Absolute/Incremental, G90/G91

-

Manual Absolute On/Off

-

Auto Coordinate System Setting

-

Max. Programmable Dimensions, 8 digits

-

48 sets Workpiece Coordinate System, G52-G59,

-

Optional Block Skip

-

Plane Selection, G17-G18, G19

-

Canned Cycles for Drilling G73, G74, G76,

-

G80-G89, G98, G99

-

Control In/Out

-

Coordinate System Setting, G92

-

Sequence Number, N5 digit

-

Label Skip

-

Pocket Calculator Type Input

-

Circular Interpolation/Radius Design

-

Program Number, 0-4 digit

Editing Functions:

-

Background Editing

-

Input-Output Interface, RS232C

-

1000 Registered programs

-

Program Number Search

-

Extended Part Programming Editing

-

Sequence Number Search

-

Part Program Storage Length,

-

5,120 meters memory storage

-

Global Search/Edit

-

Program Protect

Spindle Functions:

-

Rigid Tapping

-

Spindle Speed, 10% RPM increments

-

Spindle Orientation

-

Spindle Speed Override, 50-150%

Tool Functions/Compensation:

-

Cutter Compensation C, G40, G41, G42

-

Tool Length Measurement, Auto Type

-

Tool Length Compensation, G43, G44, G49

-

Tool Offsets G45-G48

-

Tool Offset Memory, 400

-

Tool Life Management

-

Tool Offset Memory C

Averex Standard Package Includes:

- 500mm 2-APC System

- Fanuc 0IM-F Plus / M-Pro I Control System

- 15” High Resolution LCD Screen

- 2 Meg Program Storage (5,120 Meters)

- AICC II 200 Block Look Ahead High-Speed Machining

- HRV-III+ High Performance Servo Drives

- 15,000 RPM, 50 HP/ 250 Nm BIG PLUS Direct Drive Spindle

- 2,913 IPM X, Y, Z Axis rapids with 1.25G acceleration

- 80 Tool Servo Driven ATC Magazine

- 66 RPM Full 4th Axis Rotary Table (.001) Degree Increments

- Tsubaki Core Cooled Ballscrews

- THK Heavy Duty Roller Ways with Special Contamination Covers

- Full Machine Thermal Compensation: With Chilled Spindle,

Core Cooled Ballscrews and Bearings, Y axis Servo Motor and

Spindle Motor Separator Housing.

- 435 PSI Thru-Spindle Coolant (prep for 1000psi)

- Air Cutting Through Spindle

- Marpos T-18 retractable Tool Length and Diameter Probe

- Programmable Tool Load Monitoring

- Tool Life Management

- Manual Guide i

- 1000 Registered Programs

- Program Restart

- Big Tool Function

- Ethernet and USB device

- Oil Skimmer

- Dual Chip Augers with 200 Gallon High Volume Coolant System

As detailed above Averex 540i 2 pallet HMC $300k

Also available: Averex 450i 2 pallet HMC $260k (same machine smaller travels)

Averex 540i 6 pallet HMC $400K (same machine with 6 pallets)