Shop

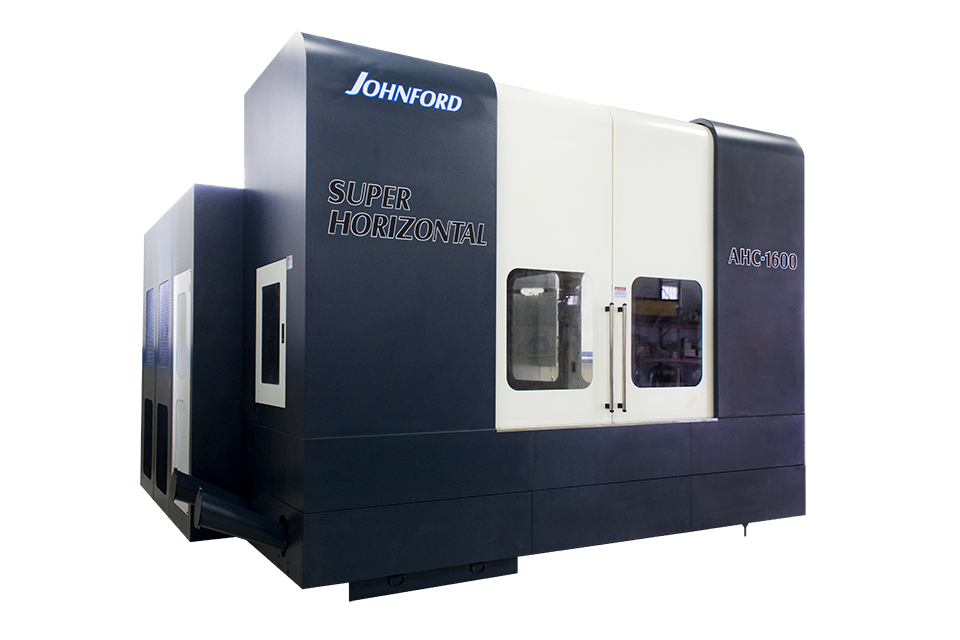

Johnford AHC-1600 HMC Moving Column Combination Table Type Horizontal Machining Center

Description

The Johnford AHC-1600 is our latest horizontal machining center. Ideal for aerospace application, the AHC-1600 can handle a wide variety of applications in many industries. With standard accessories, this rigid 35 HP horizontal machining center, weighs in at 40,000 lbs. of Meehanite cast iron. The machine design features a moving column for the Z axis and a moving table for the X axis only. This design, which is superior to a moving table / fixed column design, allows for maximum rigidity, better accuracy, and full support of the table over the complete X axis travel. The moving column design eliminates the need for outriggers or outboard supportive ways to support high table loads. The X axis is fully support by the base with absolutely no overhang of the table. The machine features precision ground and induction hardened box ways in X, Y, and Z. All mating surfaces are coated with Turcite-B and hand scraped for fit. The ways are force lubricated via a pressurized automatic oil lubrication system. Accurate positioning is carried out by large (2.0”) diameter, pre-tensioned ballscrews and powerful servo motors. Accuracy is ensured by the optional Heidenhain linear scales.

MACHINE SPECIFICATIONS

Travels

Longitudinal Travel (X) Axis 63″ (72”, 79”, 118” opt.)

Vertical Travel (Y) Axis 50”

Column Travel (Z) Axis 40″

Spindle center to table top 5.5” – 55.5”

Spindle nose to table center 7.9″ min / 47.9” max

Table (Combination)

Flat Table Working Surface 63″ x 32″ (72”, 79”, 118” length opt.)

Rotary Table Diameter 31.5”

Maximum Workload on Flat Table 10,120 LBS.

Maximum Workload on Rotary Table 4,400 LBS.

Table Surface Ground / T-slotted

No. of T-slots x Width 7 x 22mm

Spindle (Standard)

Spindle Motor 35 HP

Spindle Torque 575 ft/lbs at only 375 RPM

Spindle Taper ISO-50

Spindle Drive System 2 speed gear box

Spindle Speed 0-6000

Spindle (Optional Inline Direct Drive)

Spindle Motor 35 HP Fanuc (40HP opt.)

Spindle Torque 122 ft/lbs at 1500 RPM

(258 ft/lbs at 500 RPM optional)

Spindle Taper ISO-50

Spindle Drive System Direct Drive

Spindle Speed 0-10000

Spindle (Optional Weiss Integral Motor Spindle)

Spindle Motor 56 HP high torque

Spindle Torque 300 ft/lbs @ 1000 RPM

Spindle Taper HSK-100A

Spindle Drive System Integral Motor

Spindle Speed 0-15000 RPM

Automatic Tool Changer (arm type)

Number of Tools 40 tools (60, 80, 120 opt.)

Tool Selection Bi-directional-random

Tool Change Time 6 sec. tool to tool

Maximum Tool Diameter 4.9″ with adjacent tools, 9.8” without

Maximum Tool Weight 33 LBS

Tool Type CAT-50 (BT-50 / HSK-100A opt)

Maximum Tool Length 15.7″

Ballscrews and Axis Motors

X-Y-Z Ballscrew Diameter 2.0” X, Y, Z x 10 pitch

Ballscrew Type Class 3 double nut pre-loaded

Ballscrew Mounting Type Pre-tensioned

X-Y-Z-B Servo Motor HP 9.0 – 5.2 – 9.0 – 5.2HP

Servo Motor Mounting Direct coupled XYZ

Feeds

Rapid Traverse Rate X,Y,Z 590 IPM

Rapid Traverse Rate B axis rotary table 11.1 RPM

Cutting Feed Rate 0.01 – 472 IPM

Linear Positioning Accuracy +/- .0003″ full stroke

Linear Repeatability +/- .0002″

B axis Positioning with / without scale 5 arc seconds / 15 arc seconds

General

Coolant Tank Capacity 120 gallons

Machine Weight (base machine only) 44,000 LBS (63” X axis)

Floor Space 171″ X 170″ x 122″ (63” X axis)

Machine Power Source 208/220 Volts, 3 Phase 150 Amps**

Air Source 90 PSI

Standard Machine Accessories

Flood Coolant System with programmable air blast

Air blast for spindle

Auto Lubrication with Alarm

Automated chip removal system with 4 screw type chip conveyors

Halogen work lamp

2 speed geared head with spindle / headstock cooler

Remote Handwheel

Heat exchangers for control cabinets

Hydraulic counterbalance for headstock

Rigid Tapping

B axis rotary table (.001 degree)

40 Tool ATC

STANDARD CONTROL SPECIFICATIONS

Fanuc OiM-F Plus Conversational Control

10.4” color LCD screen

Color graphics

Fanuc Manual Guide i conversational programming

Alpha i AC digital servo system with 1,000,000

pulse encoders

Full MDI keyboard

PCMCIA data card slot on front panel

USB port on front panel

Ethernet Connection

Memory Card Editing Function (software required)

2 Megabyte part program RAM storage

1000 registerable programs

AICC-I / Advanced Preview Control (Look ahead of multi-blocks – 200 blocks look ahead)

Automatic Acceleration / deceleration with Bell Shaped rapid acc / dec

4 controllable axes (5th axis option)

3 axes simultaneous control std. (4 axis opt.)

Manual feedrate override (0-200%)

Spindle speed override (50-200%)

Optional block skip

Decimal point input

Helical interpolation

Cylindrical interpolation

Canned cycles for drilling

Automatic corner override

Scaling

Coordinate system rotation

Mirror image

Threading, synchronous

Custom Macro B

High speed skip signal

Unexpected Disturbance torque detection

Programmable data input (G10)

Direct drawing dimension programming

Work piece coordinate system (G52 – G59)

Addition of workpiece coordinate system 48 pairs (G54.1 – G54.48)

400 Tool offsets

Tool life management

Extended tool life management

Automatic tool length measurement

Backlash compensation

Machine lock

M,S,T function lock

Dry Run

Single block

Rapid Traverse Override

Spindle orientation

Rigid tapping

Clock function

Alarm history display

Operation history display

Run, hour and parts count display

RS232-C

Program restart

Background editing