Shop

DMC DL 6TH High Speed Horizontal Turning Center $50,000 made in Korea

Description

The DL 6TH is designed by FFG DMC with years of expertise and the latest technology, is designed to maximize productivity by enhancing both technical performances. All axes of DL 6TH is designed with Linear Guideway and providing more accurate cutting performance.

■ FEATURES

- Fanuc 0i-TF controller

- 10.4” LCD Monitor

- 6,000 rpm spindle

- Powerful 20 HP (15kW) spindle motor

- 6” Chuck

- Ø1.73” (Ø 44mm) Bar capacity

- Ø11.02” (Ø 280mm) Max. turning diameter

- 20.47” (520mm) Turning length

- 10 Station Servo Turret

- A2-5 spindle nose

- Linear Guideways

- Manual Tail Stock

- Programmable Quill

- Manual Guide i

- Chip Conveyor

- Bar Feeder Interface

- Manual Tool Pre-setter

- Oil Skimmer

- (4) Extra M-Codes

- Coolant Flushing Gun

- Air Gun

- Tool size: □ 1”/Ø 1.25” (□25mm/Ø32mm)

- 3 color tower signal light

- 1,181 IPM (30m/min) X, and 1,181 IPM (30m/min) Z rapid traverse

- 45° slanted All-in-One Bed structure

■ SPECIFICATIONS

CAPACITY:

Maximum Swing (on the Bed) Ø 480mm (18.89”)

Maximum Cutting Diameter Ø 280mm (11.02”)

Maximum Cutting Length Ø (20.47”)

Draw Tube I.D. Ø 45mm (1.77”)

Bar Capacity Ø 44mm (1.73”)

Chuck Size 6”

SPINDLE:

Spindle Nose A2-5 (ASA)

Bore Diameter Ø 55 mm (2.16”)

Main Spindle Motor 15/11KW (20/15 HP)

Spindle Speed 6,000 rpm

Spindle Torque (15 min. rating) 81132 ft-lbs (18.3 kgf.m)

Spindle T.I.R >3㎛ (spindle taper)

SLIDE & CARRIAGE

“X” Axis Travel 165 mm (6.5”)

“Z” Axis Travel 520 mm (20.47”)

Rapid Traverse “X” 30 m/min (1,181 IPM)

Rapid Traverse “Z” 30 m/min (1,181 IPM)

Guide Ways (X / Z) LM GUIDE

Bed Structure 45o Slant bed

TURRET

Max Number of Tool Stations 10 Tools

Turret Indexing Speed (Full) 0.2 (1.0) seconds

Indexing Type Non-stop, Bi-directional

Tool Size (Turning and Facing) □ 25 mm (1”) – Bolts clamp type

Tool Size (Boring Bar Max. Diameter) Ø 32 mm (1 1/4”)

TAILSTOCK (Manual)

Tailstock Center (Taper) MT #4

Quill Diameter Ø 65 mm (2.55”)

Quill Travel (by Hydraulic) 80 mm (3.15”)

Tailstock Body Travel 470 mm (18.50”)

Max. Thrust of Quill 511 kg (1,127 lbs.) at 35 kg/cm2

MACHINE SIZE

Floor Space Requirements (L x W) 2,260 mm (89”) x 1,670 mm (66”)

Machine Height 1,570mm (62”)

Machine Weight 3,000 kg (6,613 lbs.)

Power Consumption 23 kVA

Voltage 220V±10%, 60 Hz, 3 phase

CNC

CNC Model Fanuc 0i-TF Plus

Display Unit 10.4” LCD monitor

■ MACHINE CONSTRUCTION & FEATURES

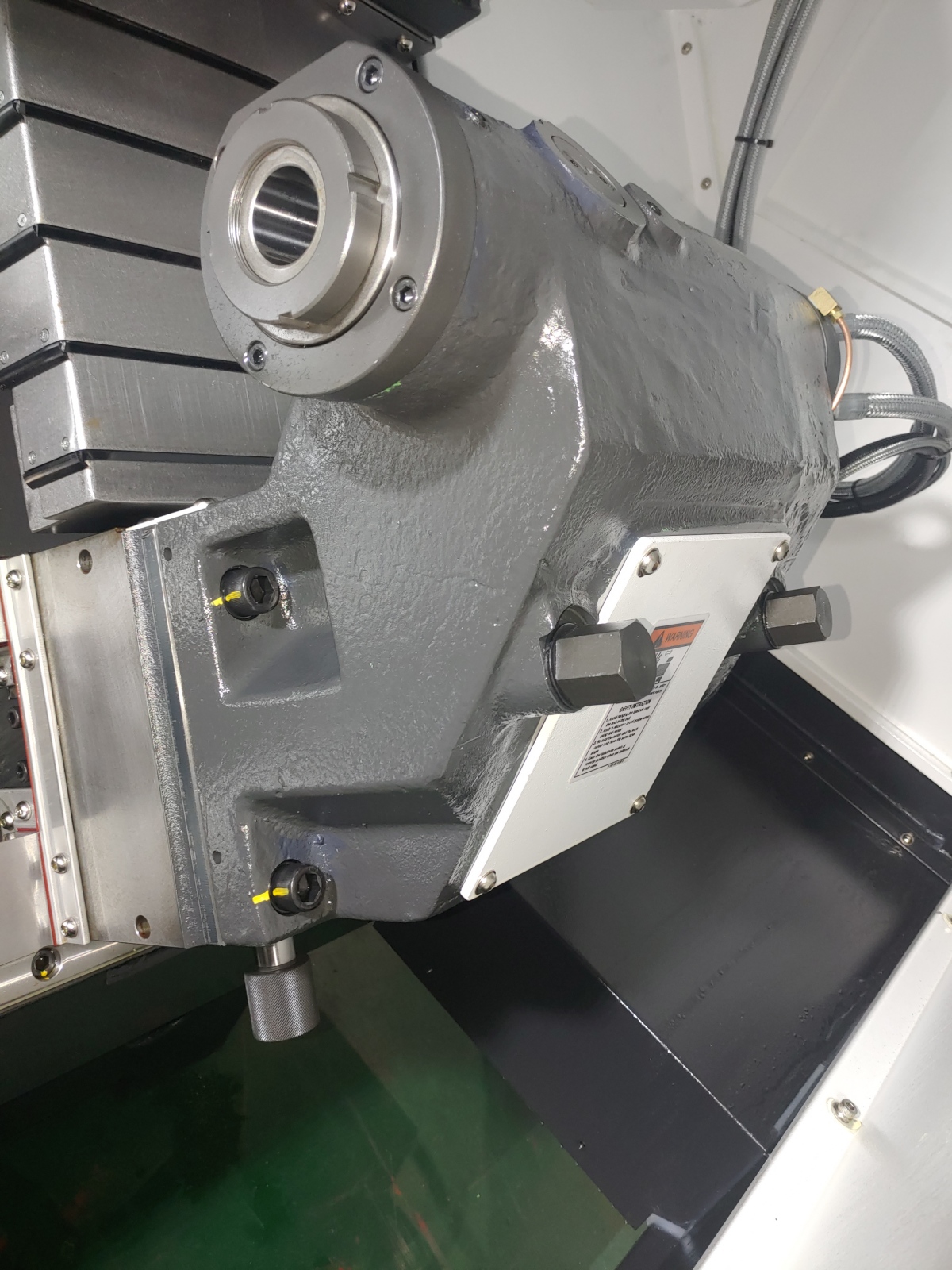

BED

- One-piece 45o rigid slant type bed casting structure.

- Heavily ribbed torque tube design to prevent thermal deformation and twisting.

- Easy access to all machine parts and easy chip removal design.

- Maximum rigidity and minimal deformation with over designed Leaner Motion Guides.

SPINDLE & HEADSTOCK

The machine headstock utilizes a precision ground spindle that is machined in a temperature-controlled environment and clean room assembled.

Spindle Nose ASA A2-5

Spindle Bore Dia. Ø 55 mm (2 .16”)

Draw Tube I.D. Ø 45mm (1.77”)

Max. Bar-work Capacity Ø 44mm (1.73”)

Spindle Speed (6” Chuck) Max 6,000 rpm

- The powerful Fanuc AC βiI 12/10,000, 11/1kW (20/15 hp) spindle motor

SERVO DRIVEN CARRIAGE

| Items | X-axis | Z-axis |

| ▪ Travel | 165mm (6.5”) | 520 mm (20.47”) |

| ▪ Rapid Traverse | 30 m/min (1,181 ipm) | 30 m/min (1,181 ipm) |

| ▪ Ball Screw (Tsubaki) | ||

| Diameter | Φ 32 mm (1.25”) | Φ 32 mm (1.25”) |

| Lead | 10 mm (0.39”) | 10 mm (0.39”) |

| ▪ Servo Motor (Fanuc) | ||

| Type | β12B / 3,000iS | β12 / 3,000iS |

| Rated Power | 1.8 kW ( 2.4 hp) | 1.8 kW (2.4 hp) |

| ▪ Slide Ways | LM Guide | LM Guide |

| ▪ Safety Device | Mechanical Stopper with Damper | Mechanical Stopper with Damper |

TAIL STOCK

Manual Body, Programmable Quill

Tailstock Quill Diameter Ø 65 mm (2.55”)

Stroke of Tailstock Quill (hydraulic) 80 mm (3.15”)

Stroke of Tailstock Body 470 mm (18.50”)

Tailstock Quill MT #4

Max. Thrust force of Tail stock Quill 511 kg (1,127 lbs.)

RIGID TURRET DESIGN – 10 Station Servo Turret

The 10-station turret accepts any combination of I.D. or O.D. tool holders. Turret rotation is bi-directional and non-stop from station to station.

The high accuracy curvic coupling with random selection and shortest path indexing. This reduces idle time, contributing to increased productivity.

Turret Type 10 stations drum turret

Turret Drive Method Servo Motor

Tool Size

– Turning/facing holder (wedge clamp) □ 25 mm (1”)

– Boring bar shank Dia. Ø 32 mm (1·1/4”)

Index Coupling Ø 180mm (Ø 16 3/4”)

3-piece Curvic Coupling

Turret Clamp Force by Hydraulic 3,271 kgf (7,211 lbs.)

Turret Index Time (1 step / full) 0.2 sec/ 1 sec

AUTO TOOL PRE-SETTER (Option)

AUTO TOOL SETTER

Auto tool setter serves as a monitoring system for tool wear compensation and tool-breakage detection

TOOL SETTING

Tool setting data is registered to the CNC by simply bringing the tool tip into contact with the tool sensor.

TOOL PRESETTER PRODUCTIVITY

Reduces set-up time

Reduces change over time from part to part

HYDRAULIC CHUCK & CYLINDER

Chuck Type SYH-245CC (6” through hole, Samchully)

Matching Soft / Hard Jaw B06B1/HB06A1

Jaw Stroke / diameter Ø 5.5 mm (0.21”)

Max. Allowable Speed of Chuck 6,000 rpm

Spindle Nose A2-5 (Mounting Adaptor)

Rotary Cylinder Type HS-06A05V1 (Samchully)

Max. Hyd. Pressure 40.8 kg/cm2 (580.17 psi)

Piston Thrust (Input / Output) 3,875 kgf (8,525 lbs.) / 3,365 kgf (7,403 lbs.)

Cylinder Bore (thru. Hole) Ø 45 mm (1.77”)

Chuck Weight (with Soft Jaw) 13.7 kgf (99.09 lbs.)

LUBRICATION

Pump unit AMGP01NS <A-RYUNG>

HMGP-303S-01-T04-P-220 <HANSUNG>

Motor Synchronous motor (AC220V, 25W, 50/60Hz)

Discharge 150CC/min

Discharge pressure Maximum 15 kg/cm2 (217.6 psi)

Tank capacity 1.8 Liters (0.5 gal)

COOLANT AND CHIP PAN

Type Removable / Independent

Coolant capacity 120 Liters (31.7 Gal)

(1) Pump motor 0.4 kW (0.54 hp)

Discharge & Pressure 40 l/min – 0.18 kg/cm2 (10.6Gal-2.56psi) at 60 Hz

■ CONTROLLER SPECIFICATIONS

- TYPE OF CONTROL / Fanuc 0i-TF Plus

- 32-bit multiprocessor continuous-path control

- HARDWARE COMPONENTS

- 4” Color LCD Monitor

- Flash memory card interface

- USB Port

- LAN Port

- SCREEN DISPLAY

- Window oriented operator interface

- Display of current block during program execution

- Screen texts: English (other languages: Option)

- Actual cutting / spindle speed display

- Alarm display and Alarm history display

- Clock (function) display

- OPERATION

- Program protection on machine control panel

- 512Kbyte part programming storage

- Number of Registered Programs: 400

- Built-in Run Hour / Parts Counter Display

- Tool life management

- Background editing

- Linear and circular interpolation

- Graphic Display

- Variable lead thread cutting (G34)

- 1 position Spindle Orientation

- Programmable data input

- Program restart

- Custom macro

- MODES

- AUTOMATIC

- Control of AUTOMATIC mode by:

– Feed hold and spindle stop

– Skip block

– Single block

– Dry run feed rate

- JOG (setup)

- MDI (manual data input)

- MACHINE CONFIGURATION FOR AXES

- Inch or metric programming

- Switchover between metric and inch for input and offsets, display, programmed traverse path

- Feed-rate and rapid traverse: minimum input feed-rate in inches/min = 0.0001 inches/min.

- Revolution feed-rate: minimum input feedrate in inches/rev = 0.0001 inches/min.

- MACHINE SPINDLE CONFIGURATIONS

- Constant cutting speed, cutting feed-rate clamp

- Thread cutting, traverse, cross, tapered with thread constant

- Thread pitch constant: smallest pitch in inches/rev = 0.0001 inches/rev

- OVERRIDES, OFFSETS AND COMPENSATIONS

- Feed-rate override 0% to 150%

- Rapid traverse override 0%, 25%, 50%, 100%

- Spindle speed override 50% to 120%

- 64 pairs of Tool Offsets

- Tool nose radius compensation, Tool geometry/wear compensation

- Chamfering / Corner R compensation

- Backlash compensation

- CNC PROGRAMMING

- Diameter/Radius command

- Insertion of comments in the program

- Chamfer radius programming, Chamfer on/off

- Mirror image by each axis

- Stored stroke check 1, 2nd reference position return

- Work coordinate system (G50), Work coordinate system selection (G52 ~ G59)

- Skip function, Optional block skip

- Sub-program call (4 level)

- Searching function: Program no., Sequence no., and external work no.

- Simple canned cycle (G90, G92, G94)

- Multiple repetitive canned cycle (G70 ~ G76)

- Absolute and incremental programming

- Feed per minute (G98) / Feed per revolution (G99)

- Dwell time can be programmed in seconds or revolutions

- Single block by each axis, dry run

- SAFETY AND DIAGNOSTIC FUNCTIONS

- Safety routines permanently active for measuring circuits, over temperature, battery, voltage, memory, limit switches, fan monitoring

- Self-diagnostics

- Contour monitoring

- Spindle monitoring

- OPTIONAL FUNCTION

- Dynamic graphic display

- Fast Ethernet (hardware)

■ STANDARD FEATURES (US Standard)

- Fanuc 0i-TF controller

- 10.4” LCD Monitor

- 6,000 rpm spindle

- Powerful 20 HP (15kW) spindle motor

- 6” Chuck

- Ø1.73” (Ø 44mm) Bar capacity

- Ø11.02” (Ø 280mm) Max. turning diameter.

- 20.47” (520mm) Turning length

- 10 Station Servo Turret

- A2-5 spindle nose.

- Linear Guideways

- Manual Tail Stock

- Programmable Quill

- Manual Guide i

- Chip Conveyor

- Bar Feeder Interface

- Manual Tool Pre-setter

- Oil Skimmer

- (4) Extra M-Codes

- Coolant Flushing Gun

- Air Gun

- Tool size: □ 1”/Ø 1.25” (□25mm/Ø32mm)

- 3 color tower signal light

- 1,181 IPM (30m/min) X, and 1,181 IPM (30m/min) Z rapid traverse

- 45° slanted All-in-One Bed structure.

- Machine Leveling plate.

- Manuals: One (Installation/Operating, Maintenance/Tooling, Mechanical Parts List, Electric Wiring Diagram, Programming Guide for NC)

- Standard Tooling Package

- D. Tool Clamper: □25×25 (1”) 5 ea.

- Boring Bar Holder: Ø 32 mm (1·1/4”) 4 ea.

- Facing Holder: □25×25 (1”) 1 ea.

- Boring Bar Sleeve: Ø 25 mm (1”) 1 ea.

- Boring Bar Sleeve: Ø 20 mm (3/4”) 1 ea.

- Boring Bar Sleeve: Ø 16 mm (5/8”) 1 ea.

- Boring Bar Sleeve: Ø 12 mm (1/2”) 1 ea.

- Boring Bar Sleeve: Ø 10 mm (3/8”) 1 ea.

- Boring Bar Sleeve: Ø 8 mm (5/16”) 1 ea.