Shop

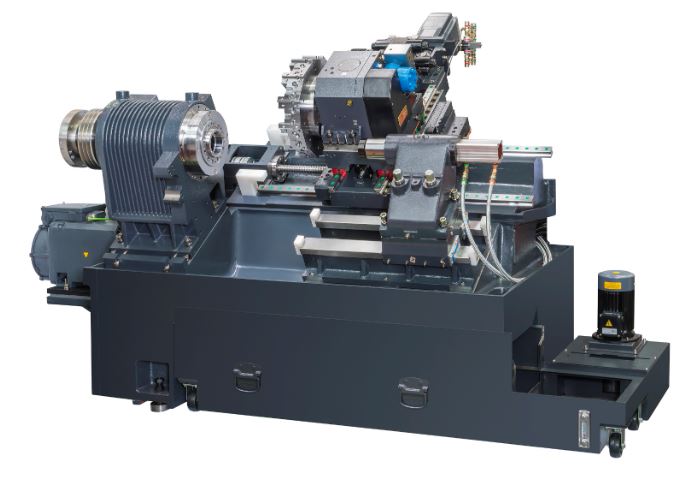

Leadwell T7A-208 CNC Linear Way Turning Center $40,000.00

Description

STANDARD FEATURES

| 20HP FANUC SPINDLE MOTOR | FANUC oi TF Plus 10.4” LCD COLOR MONITOR W/ USB |

| 4,000 RPM SPINDLE | 64 Bit MICRO PROCESSER |

| 8” Diameter chuck w/ 2.56” bar capacity | 2Mbyte MEMORY w/ PCMCIA CARD SLOT |

| 14.9” Max Turning Diameter |

RS 232C & EMBEDDED ETHERNET CONNECTIONS |

| 17.3” Max Turning Length Available | MPG HANDWHEEL |

| 12 TOOL STATION BI-DIRECTIONAL TURRET | CUSTOM MACRO B & SKIP FUNCTION |

| HIGH RIGID 30 DEG SLANT BED CONSTRUCTION | AUTOMATIC CENTRAL LUBRICATION SYSTEM |

| TAILSTOCK with PROGRAMMABLE QUILL | HEAT EXCHANGER FOR ELECTRICAL CABINET |

| chip conveyor with bucket | |

SPECIFICATIONS

CAPACITY

Max Work Swing 19.7”

Swing Over Cross Slide 12.7”

Max. Turning Diameter 14.9″

Max. Turning Length 17.3″

Max. Workpiece Weight w/o Tailstock 485 lbs

TRAVELS

X axis 8.27″

Z axis 17.7″

SPINDLE

Standard

Spindle Nose A2-6

Chuck diameter & Bar Capacity 8” / 2.56”

Spindle Bore 2.99”

Spindle Speed (rpm) 4,000

SPINDLE MOTOR

Spindle Motor FANUC Beta 22i Spindle Motor

Horsepower 20 HP

Maximum Spindle Torque 188 ft/lbs @ 563rpm

FEED RATES

X axis 1181 IPM

Z axis 1181 RPM

Jog Feed Rates 50 IPM

TURRET

Standard

Tool Stations 12

Number of Live Tool Stations n/a

Tool Size (square dimension) 1.0”

Tool Size (round dimension) 1.5”

Indexing Accuracy +/- 6.0 arc sec.

Indexing Time Tool-to-Tool .5 sec.

Indexing Time 180 deg. 1.5 sec.

TAILSTOCK

Manual

Tailstock Movement & Travel 14.1″

Quill Taper MT #4

Quill Drive Type Hydraulic

Quill Diameter & Stroke 2.95″ dia – 2.95″ stroke

Max. Quill Thrust 864 lbs.

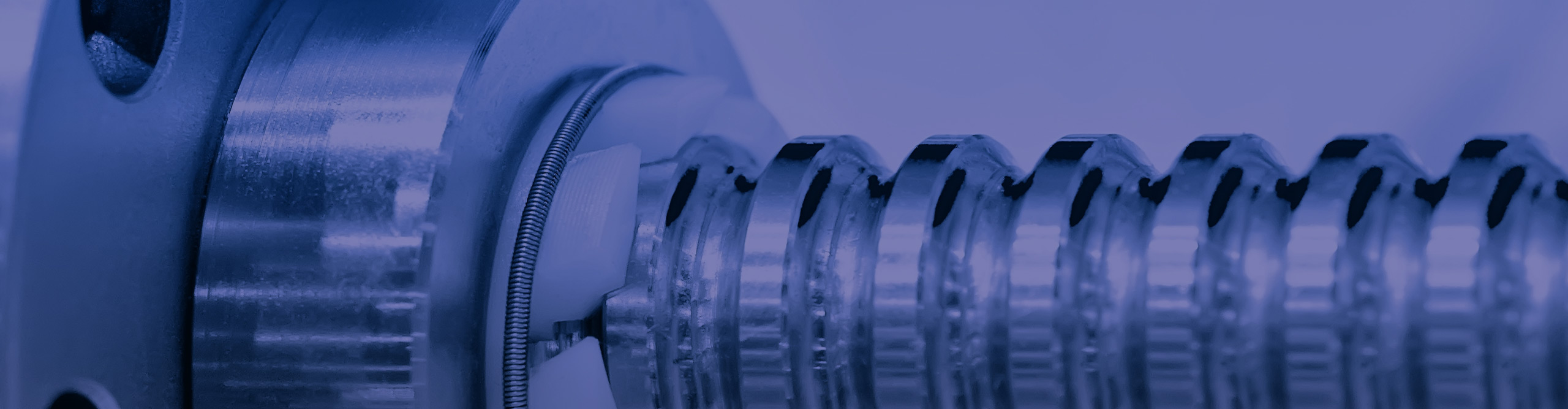

AXES SPECIFICATIONS

X axis Ball Screw 1.26” dia x .394” pitch

Z axis Ball Screw 1.26” dia x .472” pitch

X axis Motors 7.2 Hp.Fanuc A/C Brushless *

Z axis Motors 7.2 Hp. Fanuc A/C Brushless *

COOLANT SYSTEMS

Pump Motor Output 1.3 Hp.

Pump Flow Rate 7.1 gpm

Pump Pressure 29 psi.

Tank Capacity 22 gal.

POWER & AIR REQUIREMENTS

220 VAC Line Voltage AC 3 Phase

Power Consumption 30 KVA ( 78 amps. @ 220 volts)

Air Requirement 85.3 PSI Air Pressure @ 28 cfm Air Flow

ACCURACY (Full travel ~ laser calibrated)

Positioning X/Y/Z +/-0.0002

Repeatability X/Y/Z +/-0.0001

GENERAL

Floor Spacing (L x W x H) including chip conveyor:

101” x 63” x 63”

Machine Net Weight 8,157 lbs.

STANDARD CONTROL FEATURES

|

* Fanuc OiTF Plus * 10.4″ LCD Color Screen / Small MDI Key |

Interpolation functions: | ||||||||

| * 64 bit microprocessor | * Dwell | ||||||||

| * Program storage length: 2MByte | * Polar Interpolation | ||||||||

| * 2 simultaneously controllable axes | * Cylindrical Interpolation | ||||||||

| * PCMCIA Card Slot | * Skip (G31) | ||||||||

| * Embedded Ethernet (100-T base) | * Reference Point Return | ||||||||

| * Least programmable increment: 0.0001″ | * Continuous Thread Cutting | ||||||||

| * Mirror image | * Multiple Threading | ||||||||

| * Backlash compensation |

Feed function: |

||||||||

| * Stored pitch error compensation | * Rapid traverse override | ||||||||

| * Self diagnostic functions | * Feed per minute / Feed per revolution | ||||||||

| * Automatic acceleration / deceleration | |||||||||

| * Feedrate override | |||||||||

| Program input: | * Jog override | ||||||||

| * Rigid tapping | |||||||||

| * Inch/metric conversion / programming | |||||||||

| * Tape code: EIA, ISO Automatic recognition | |||||||||

| * Absolute/incremental programming (G90, 91) | Editing operation: | ||||||||

| * Decimal point programming | * Number of registerable programs: 400 | ||||||||

| * Coordinate system setting (G92) | * Program protect | ||||||||

| * Work Coordinate systems G54-59 (Fixture Offsets) | * Background Editing | ||||||||

| * Work Coordinate system additional (P1 – P48) | * Extended part program editing | ||||||||

| * Programmable Data input G10 | |||||||||

| * Subprogram call – 4 folds nested | Standard operation features: | ||||||||

| * Custom Macro B | * Keyboard type manual data input (MDI) | ||||||||

| * Custom Macro variables additional (total 600) | * JOG feed | ||||||||

| * Multiple repetitive cycles & II (G70-G76) | * Manual pulse generator | ||||||||

| * Canned cycles (G90, G92, G94)

* Peck drilling canned cycle (G83) * Keyboard type manual data input (MDI) |

* Spindle speed override | ||||||||

| * Run hour and parts count display | |||||||||

| Tool function / Tool compensation: | * Input/output interface (RS232C) | ||||||||

| * Tool offsets pairs (64 total offsets) | |||||||||

| * Tool nose radius compensation (G40-G42) | |||||||||

| * Tool Life Management | |||||||||

| * Tool offset value counter input | |||||||||

| * Geometry and wear offsets | |||||||||

STANDARD EQUIPMENT

- Fanuc OiTF Plus Control w/ 10.4” Color LCD display w/ 2Mbyte Program memory

- 20Hp spindle motor

- 4,000 rpm Max Spindle Speed

- A2-6 spindle nose with 2.99” spindle bore

- 8” Diameter Chuck w/ 2.56” Bar Capacity

- Chip Conveyor & Bucket

- Manual Tailstock with Programmable Quill

- Spindle orientation

- Spindle speed override 50 – 150%

- Rigid tapping

- Custom Macro B (User Definable)

- Program and data protection key switch

- USB, PCMCIA, RS-232 & Embedded Ethernet Connections

- Linear Guide Ways X & Z

- Double Pre-tensioned ballscrews

- Metered piston distributor lubrication

- Telescopic covers

- Full enclosure guarding

- Flood coolant with large separate coolant tank

- Alarm & Work Light

- Instruction manual, parts list, and electrical drawings

- Fanuc operator and maintenance manuals on DVD

- (3) set of Soft Jaws & (1) set of Hard Jaws

- (6) 1.5” ID Boring Bar Holders

- (2) 1” ID Face & ID Tool Holder

- (1) Set of Boring Bar Bushings (3/8”, 5/8”, ¾”, 7/8” 1”, 1-1/4”, MT-1, MT-2, MT-3, MT-4)