Shop

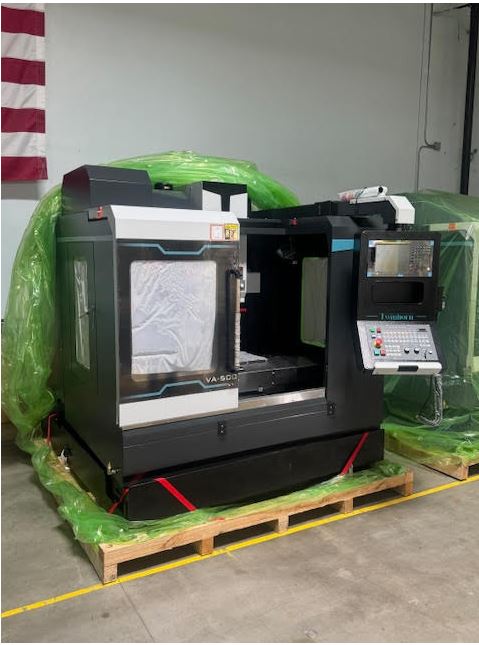

NEW Twinhorn VA500 $55k

Category: CNC Mills

Description

TWINHORN VA-500 VERTICAL MACHINING CENTER

STANDARD FEATURES ► Fanuc Oi-MF Plus 10.4” Color LCD ► Fanuc 20HP Spindle Motor ► 512Kbyte / 800 Meter Memory ► Spindle CAT-40 with 8000 RPM ► PCMCIA Slot for Memory Expansion ► AC Digital Servo & Spindle Drivers ► Helical Interpolation & Custom Macro B ► Arm Type 24 Tool ATC ► Hardened Ground Box Ways on X,Y & Z ► Auto Lubrication System ► Meehanite Cast Iron Bed, Base & Headstock ► Fully Enclosed Splash Guard ► Heat Exchanger for Electrical Cabinet ► Spindle Air Blast & Cutting Air Blast ► Automatic Power off (M30) ► Spindle Air Curtain ► Roll Out Coolant Tank & Chip Tray ► RS232 Interface ► Fanuc Operating & Maintenance Manual ► Operating & Electrical Manuals ► 4th Axis Interface Cable only Ready ► Hand Held Coolant & Air Nozzle ► One Year Machine Parts Warranty

MACHINE SPECIFICATIONS

Travel X Axis ———– 19.69” (500mm)

Travel Y Axis ————15.75” (400mm)

Travel Z Axis ————17.72” (450mm)

Rapid Feed Rate X & Y Axis 945ipm

Rapid Feed Rate Z Axis 787ipm

Cutting Feed Rate ——315ipm (8000mm/min)

Positioning X, Y & Z Axis 0.0001/12” (0.005mm / 300mm)

Repeatability X, Y & Z Axis±0.0001” (±0.003mm)

Table Dimension ——–27.56” x 15.75” (700mm x 400mm)

Maximum Loading —–660 lb (300Kg)

Spindle Motor FANUC AC Spindle Motor ßiI 8 / 8000

Spindle Horse Power — 20 HP

Spindle Speed ——-8000Rpm (Opt. 12000Rpm)

Spindle Taper ——-CAT-40

Servo Drive Motor X & Y Axis Fanuc ß 12 / 3000is

Servo Drive Motor Z Axis —- Fanuc ß 22 / 3000is

Distance from Spindle Nose to Table –4.72” – 22.44” (120 – 570mm)

ATC -Swing Arm Type Random, Shortest Path, Bi-Directional

Magazine Capacity —– 24 Tools

Tool Change Time ——- 2.5 Second

Maximum Tool Weight — 15.4 lb (7.0kg)

Maximum Tool Length — 8.86” (225mm)

Maximum Tool Diameter -3.14” (80mm)

Floor Space L x W x H 76.97”x90.16”x94.09” (1,955mmx2,290mmx2,390mm)

Power Requirement 220V, 3 Phase, 60Hz, 30kVA, 75Amp

Machine Weight —-8,360 lb (3,800 kg)

MACHINE PRICES

VA-500 Fanuc Oi-MF Plus Control / 8000RPM / 24 Tool Arm Type ATC $55,000

-

OPTIONAL ACCESSORIES

-

Spindle Speed 12000RPM (included Spindle Oil Refrigeration Unit)------$7,380

-

Data Server 256MB (DNC) .................$3,800

-

Chain Type Chip Conveyor & Cart....... $5,800

-

Spindle Oil Refrigeration Unit..............$2,600

-

Coolant Through Spindle Without Extra Tank & 300PSI Pump... $9,700

-

Coolant Through Spindle With Filter System, Extra Tank & 300PSI Pump $13,800

-

Chip Flushing System ..........................$1,150

-

Coolant Ring......................................... $850

-

Oil Skimmer .........................................$1,150

-

4th Axis Interface with Servo Drive & Power/Signal Cable...............$6,600

-

4th Axis Complete with Manual Tailstock + Install (Tanshing VRNC-210) $19,800

-

8" 3 Jaw Chuck for Tanshing VRNC210...$1,180

-

Flange for 3 Jaw Chuck Tanshing VRNC210 .....$850

-

Transformer 30KVA.............................$2,450

Fanuc Oi-MF Standard Features *Max Controlled axis (5 axes) *Controlled path (1path) *Max Controlled axis in each path (5 axes) *Axis control by PMC Max 4 axes *Max Simultaneously controlled axes (Max 4 axes) *Designation of Spindle axes (2 axes) *Cs contouring control (each path/Total 1 axis) *Axis synchronous control *Tandem control, Torque control *Control axis detach *Increment system IS-A, IS-B *Increment system C 0.0001mm, 0.0001deg, 0.00001inch *Flexible feed gear (Optional DMR) *HRV2 control, HRV3 control *Inch/metric conversion *Interlock & Machine lock all axes *Emergency stop / Overtravel *Stored stroke check / Stroke limit external setting *Mirror image each axis *Servo off / Mechanical handle *Unexpected disturbance torque detection function *Position switch *Automatic operation, MDI operation *DNC operation, DNC operation with memory card *Schedule function, Program number search *Sequence number search, Program restart *Manual intervention and return *Wrong operation prevention *Retraction for Rigid tapping, Buffer register *Dry run, Single block, Jog feed *Manual reference position return *Reference position setting without DOG *Reference position setting with mechanical stopper *Reference position return speed set *Reference position shift *Manual handle interruption *Manual handle feed *Incremental feed *Jog and handle simultaneous mode *Nano interpolation *Positioning G00 *Single direction positioning G60 *Exact stop mode G61 *Tapping mode G63 *Cutting mode G64, Exact stop G09 *Skip G31, Reference position return G28 *Reference position return check G27 *Plane selection G17, G18, G19 *Linear interpolation, Circular interpolation *Dwell in seconds and dwell in revolution *Cylindrical interpolation *Helical interpolation *Thread cutting, synchronous cutting *High-speed skip, input signal is 4 point *Torque limit skip *2nd/3rd/4th reference position return *Normal direction control *Index table indexing, General purpose retract *Rapid traverse rate, Rapid traverse override *Feed per minute, Feed per revolution *Without position coder feed per revolution *Without position coder constant surface speed control *Tangenitial speed constant control *Cutting federate clamp *Automatic acceleration/deceleration *Rapid traverse bell-shaped acceleration/deceleration *Linear acceleration/deceleration after cutting feed interpolation *Feedrate override 0-254% *One-digit F code feed, Inverse time feed *Jog override 0-655.34% *Override cancel, External deceleration *Automatic corner deceleration *Feedrate control with acceleration in circular interpolation *Rapid traverse block overlap *Al advanced preview control *Tape code EIA/ISO *Label skip, Parity check, Control in/out *Optional block skip 9 *Max programmable dimension ±9 digit *Program number O4 digit *External memory and sub program calling function *Sequence number N5 digit *Absolute/incremental programming *Decimal point programming/ pocket calculator type decimal point programming *Input unit 10 time multiply *Diameter/radius programming *Rotary axis designation, Rotary axis roll-over *Polar coordinate command *Coordinate system setting *Automatic coordinate system setting *Workpiece coordinate system G52-G59 *Workpiece coordinate system preset *Addition of workpiece coordinate system 48 pairs *Direct input of workpiece origin offset value measured *Manual absolute on and off *Optional chamfering/corner R *Programmable data input G10 *Programmable parameter input *Sub program call 10 folds nested *Custom macro *Addition of custom macro common variables #100 - #199, #500 - #999 *Interruption type custom macro *Canned cycle for drilling *Circular interpolation by R programming 9 digit *Automatic corner override *Scaling *Coordinate system rotation *Programmable mirror image *Tape format for Fanuc Series 10/11 *Small-hole peck drilling cycle *Pattern data input *Conversational programming with graphic function *Auxiliary function (M8-digit) *2nd auxiliary function (B8-digit) *Auxiliary function lock *High speed M/S/T interface *Multiple command of auxiliary function *Spindle speed function S5 digit, binary output *Spindle serial output S5 digit, serial output *Spindle analog output S5 digit, analog output *Constant surface speed control *Spindle override (0 – 254%) *Spindle orientation (1 spindle) *2nd spindle orientation *Spindle output switching function (1 spindle) *2nd spindle output switching function *Spindle synchronous control *Rigid tapping *Tool function (T8 digit) *Tool offset pairs (400 pairs) *Tool length offset *Tool offset *Tool radius/Tool nose radius compensation *Tool length measurement *Automatic tool length measurement *Tool life management *Extended tool life management *Backlash compensation *Backlash compensation for each rapid traverse and cutting feed *Store pitch error compensation *Part program storage 320Kbyte *Number of registerable programs (400) *Part program editing *Program protect, Password funtion *Extended part program editing *Playback *Background editing *Status display, Clock funtion *Current position display *Program comment display (program name 31 characters) *Parameter setting and display *Parameter check sum function *Alarm display, Alarm history display *Operator message history display *Operation history display *Run hour and parts count display *Actual cutting federate display *Display of spindle speed and T code at all screens *Directory display of floppy cassette *Directory display and punch for each group *Operating monitor screen *Servo setting screen, Spindle setting screen *Servo waveform display *Maintenance information screen *Software operator’s panel *Software operator’s panel general purpose switch *Extended software operator’s panel general purpose switch *Multi-language display *Dynamic display language switching *Data protecting key (4 types) *Erase CRT screen display (manual or automatic) *Parameter setting support screen *Help function *Self-diagnosis function *Periodic maintenance screen *Display of hardware and software configuration *Servo information screen *Spindle information screen *Graphic display *Reader/puncher interface Ch 1, Ch2) *External tool offset *External machine zero point shift *External massage *External data input (including external tool offset, external message) *External key input *External program input *External workpiece number search *External program number search (1 – 9999) *Memory card input/output *Screen hard copy *Power Mate CNC manager *External I/O device control *Embedded Ethernet