Shop

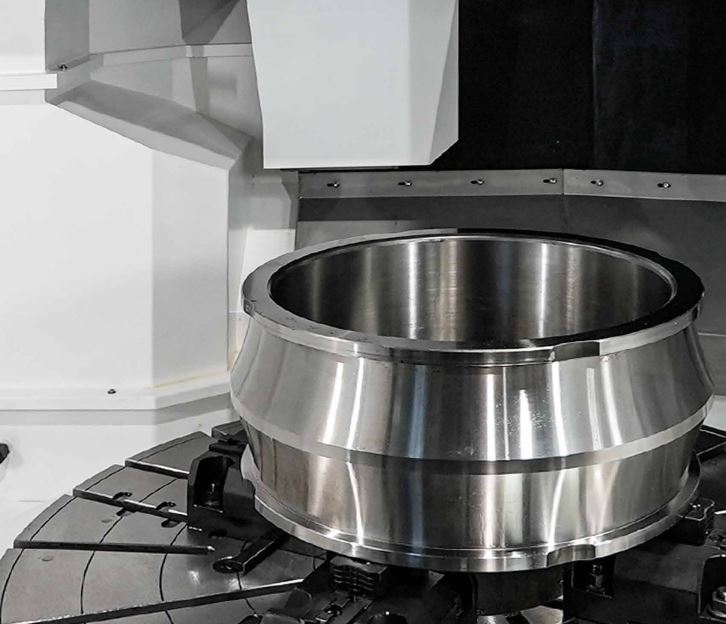

YouJi YV-1600ATC Vertical Turning Center with 12 Station Tool Changer

Description

The YV1600ATC Vertical Turning Center is a large, high precision, heavy duty machine. The rigid vertical column and base are meehanite castings, heavily ribbed for reduced thermal distortion and vibration dampening. It is built for heavy duty turning of large size workpieces.

Machine Specifications:

Capacities

Maximum swing 78.7″

Standard turning diameter 63″

Maximum turning diameter 71″

Maximum cross travel (X axis) -3.94″ ; + 44.3″ (+60” for ATC)

Maximum longitudinal travel (Z axis) 35.4″

Maximum cross rail travel (manual control) 31.5”

Maximum cutting height 50”

Ram distance to table (max / min) 60” / 0”

Spindle

Spindle Motor 60 HP

Spindle load 17,600 lbs

Spindle RPM 2-250

Spindle bearing diameter 30” O.D. / 23” I.D.

Spindle torque 12,900 ft./lbs.

Manual chuck 63” 4-Jaw Independent

ATC

Tool positions 12

ATC type Umbrella / Electric

Tool mounting #50 taper

O.D. tool shank size 1.25”

I.D. tool shank size 2.5”

Tool change time 30 Seconds

Maximum single tool weight 110 lbs.

Maximum magazine capacity 800 lbs.

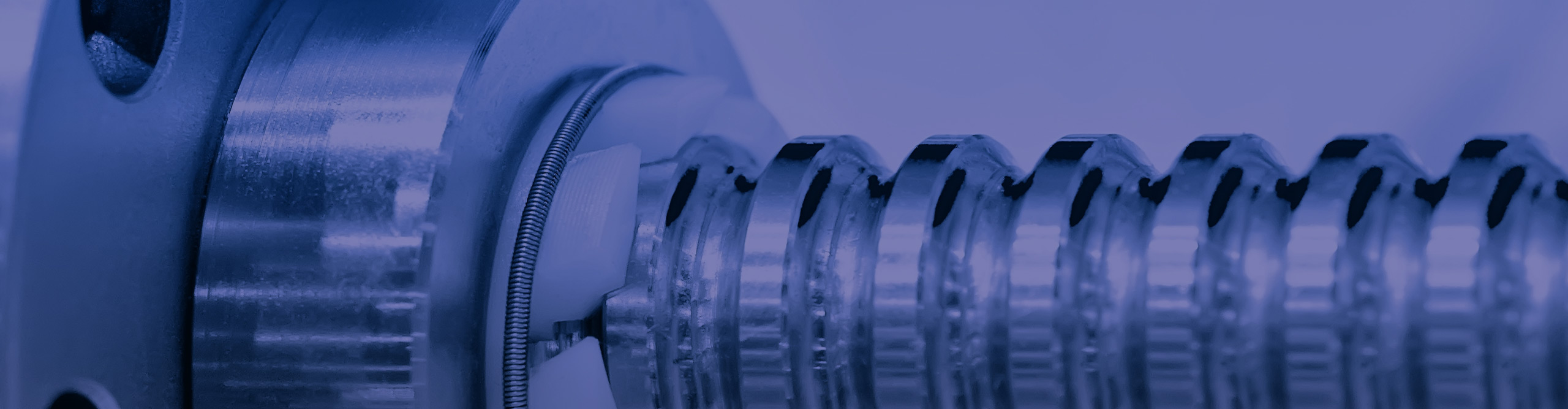

Ballscrews and axis motors

Z axis ballscrew diameter 63mm (2.48”) x 10 pitch

X axis ballscrew diameter 63mm (2.48”) x 10 pitch

Ballscrew type Class 3 double nut

Ballscrew mounting type Pre-loaded, double anchored

X-Z servo motor HP X 9 HP, Z 9 HP

Feeds

Rapid Traverse Rate X,Z 472, 394 IPM

Cutting feed rate 0.01 – 197 IPM

Positioning accuracy +/- .0003″ full stroke

Repeatability +/- .0002″

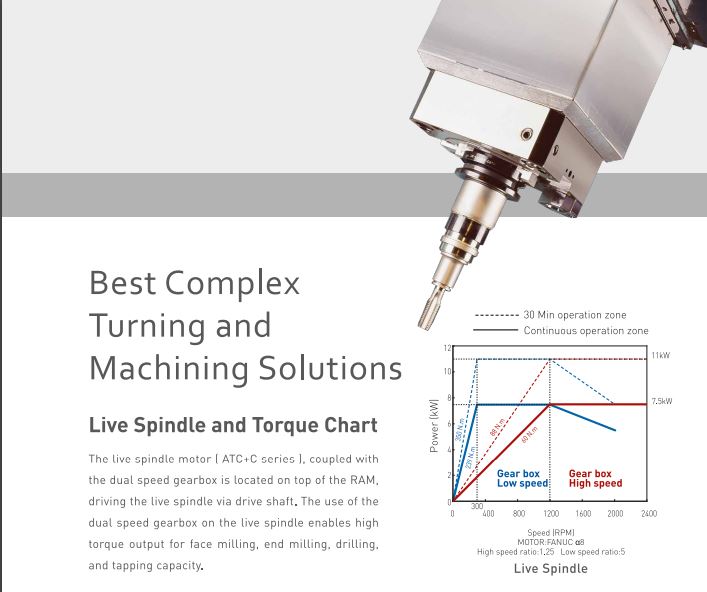

C axis and Live Tools (option)

Spindle motor 15HP

Drive System 2 speed ZF gearbox

Spindle RPM 2-2400

Tool shank type BT-50

C axis (contouring) .001 degree

General

Coolant tank capacity 160 gallons

Coolant pump motor 1.33 HP and .75 HP

Machine Weight 60,600 LBS

Floor Space 209″ X 217″ x 213″

Machine Power Source 208/220V, 3Phase, 200 Amps**

**Consult factory for exact power requirements when ordering**

Hydraulic pump motor 3HP

Standard Machine Accessories

Spindle orientation

63” face plate with 4 independent boring mill jaws

Full square guard enclosure with chip wash

Coolant system

Tool kit

Halogen lamp

1 set operation manual

3 color operation light

12 station ATC

Chip conveyor with chip bucket

Heat exchanger for electrical cabinet

Automatic lubrication system

Standard Control Specifications – Fanuc OiT-F Plus

10.4” color high resolution LCD

Manual Guide i Conversational Programming

Alpha i AC digital servo and spindle systems with 1,000,000 pulse encoders

2 Megabyte program memory

Full MDI keyboard

PCMCIA card on front panel

USB port on front panel

Ethernet Connection (embedded)

Data Card editing function (software required)

200 block look ahead

Graphics function (3D)

2 axes simultaneous control

Constant surface speed

X axis radius/diameter programming

Decimal point input

Manual feedrate override (0-200%)

Optional block skip

Auto acceleration/deceleration

G70-G76, G90,G92,G94 canned cycles for turning, drilling, threading and grooving

Tool geometry/wear offsets 64 pairs

Tool nose radius compensation (G40-G42)

Tool life management

Work Coordinate System Offsets (G52-G59)

Polar Coordinates

Chamfering / Corner rounding

Custom Macro B

Additional Macro Common Variables #100 – #199, #500 – #999

Canned Cycles

Multiple Repetitive Cycle

Multiple Repetitive Cycle II

Canned Cycles for Drilling

Backlash compensation

Spindle speed override (50-150%)

Machine lock

M,S,T function lock

Dry Run

Single block

Rapid Traverse Override (0-100%)

1000 registerable programs

RS232-C

Skip signal and high speed skip signal

Background editing

Run Hour and parts count display

Fanuc OiT-F Plus Conversational Specifications (Standard)_______________________________________

Fanuc Manual Guide i Conversational with 10.4” color LCD

- Accommodates both simple and highly sophisticated machining programs

- All operations from programming to execution can be done on screen

- Real and high speed Animated Drawing function for easy program check

- Can support sub spindle programming

- Can support C axis and live tool programming

- Full prompt through menu driven and graphical programming

For additional details and pricing:

Mike Venezia (860) 670 6909 mike@machineelectrical.com